Explore the Technical Specifications of the Best Servo Drives and How to Choose the Right One for Your Needs

In the realm of automation and precision control, servo drives play a pivotal role in enhancing performance and ensuring accuracy in various applications. This ultimate guide will delve into the technical specifications of the best servo drives available on the market, providing valuable insights into their functionalities, advantages, and key features. As we navigate through the intricate details of servo drives, we'll also equip you with essential criteria to consider when selecting the right drive to meet your specific needs. Whether you're automating a manufacturing process, robotics, or any application requiring precise movement, understanding the myriad of options and their unique characteristics can make all the difference in achieving optimal results. Join us as we explore the world of servo drives and unlock the knowledge necessary for making informed decisions in your automation journey.

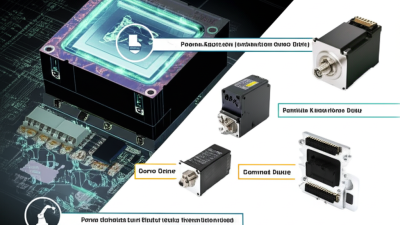

Understanding Servo Drives: Key Features and Components

When delving into the world of servo drives, understanding their key features and components is crucial for selecting the optimal solution for specific applications. Servo drives are integral to motion control systems, providing precise control of angular or linear position, velocity, and acceleration. According to a market report by Research and Markets, the global servo drive market is projected to reach $12.92 billion by 2026, growing at a CAGR of 7.4%. This underscores the increasing relevance of high-performance servo technologies across various industries, such as robotics, aerospace, and automation.

Key components of a servo drive include the controller, motor, and feedback device. The controller interprets motion commands and regulates the motor's operation to achieve the desired performance. Motors are typically classified as AC or DC, with a growing trend toward AC motors due to their efficiency and reliability. Moreover, the integration of advanced feedback devices, like encoders and resolvers, enhances accuracy and system responsiveness. A report from Industry Research states that the integration of IoT with servo drives is expected to enhance operational efficiency by up to 30% in industrial settings, making it imperative for businesses to prioritize these features as they upgrade their systems. Understanding these specifications ensures the right servo drive is selected, optimizing both performance and cost-effectiveness.

Comparison of Types of Servo Drives: AC vs. DC

When selecting a servo drive for your application, understanding the differences between AC and DC servo drives is essential. AC servo drives are typically favored for their robustness and efficiency, particularly in high-speed and high-precision environments. They utilize alternating current, enabling smoother operation and reduced maintenance needs. AC drives excel in applications that require continuous operation and can handle varying loads, making them ideal for automation and robotics.

On the other hand, DC servo drives are known for their simplicity and ease of control. These drives use direct current, which allows for quicker responses and precise torque control, making them suitable for applications that require fast acceleration and deceleration. However, their limitations include a shorter lifespan due to wear on brushes and a need for more maintenance compared to their AC counterparts. Businesses must consider the specific demands of their operations, including speed, torque, and operational efficiency, to make an informed choice between AC and DC servo drives.

Evaluating Performance Metrics: Torque, Speed, and Efficiency

When choosing a servo drive, performance metrics such as torque, speed, and efficiency are crucial factors to consider.

Torque determines the force that the servo motor can exert to perform work. A higher torque rating allows for better performance under load, making it essential for applications like robotics or CNC machines where precise control over movement is necessary.

Understanding the required torque for your specific application will help in selecting a servo drive that can meet those demands effectively.

Speed is another vital metric that must not be overlooked. It refers to how quickly the servo can reach its desired position. Different applications may require different speed capabilities; for instance, automotive assembly lines may need rapid movements, while intricate machining tasks might prioritize slower, more accurate positioning. Evaluating the speed requirements against the servo drive capabilities ensures optimal performance in your setup.

Lastly, efficiency is paramount in reducing operational costs and energy consumption. Selecting a servo drive with high efficiency ratings can lead to substantial savings over time and a smaller carbon footprint, making it a wise choice for both performance and sustainability.

Factors to Consider When Selecting a Servo Drive for Your Application

When selecting a servo drive for your application, it's essential to consider several factors to ensure optimal performance. First, assess the power requirements of your system. The servo drive must match the voltage and current specifications of the motor to prevent any potential failures. Additionally, consider the control method—whether you need position, velocity, or torque control—as this will influence the type of drive best suited for your needs.

Another important factor is communication protocols. Modern servo drives often support multiple protocols like EtherCAT or CANopen, which can affect how easily the drive integrates with your existing machinery. Ensuring compatibility with your control system is crucial for seamless operation.

Tips: Always review the manufacturer's specifications and datasheets to understand the drive's capabilities fully. Conducting a thorough application assessment can help determine the required features such as feedback types and response times. Lastly, budget considerations should also play a role in your decision, balancing cost with the performance benefits provided by higher-end options.

Real-World Applications: Choosing the Right Servo Drive for Industry Needs

In today's industrial landscape, selecting the right servo drive is essential to enhance operational efficiency and achieve precise control over machinery. According to a recent report from MarketsandMarkets, the global servo drive market is projected to grow from $10.1 billion in 2021 to $14.4 billion by 2026, highlighting the increasing demand for automation in various industries. The choice of servo drive not only impacts performance but also the overall energy consumption of automated systems, as optimized drives can reduce energy costs by up to 30%.

Different sectors require tailored servo solutions that align with their specific operational demands. For example, the automotive industry, which has seen a surge in automation, commonly employs high-performance servo drives to ensure rapid and flexible production lines. These servo drives must withstand high torque and provide real-time feedback for precision. Similarly, the packaging sector requires servo drives that are capable of high-speed operations and quick changeovers, enhancing productivity while minimizing downtime. Industry experts emphasize the need to assess factors such as load requirements, speed, and precision to make an informed decision when choosing a servo drive that meets the unique needs of any application.

Servo Drive Performance Comparison

This chart compares the performance metrics of different servo drives in terms of Speed, Torque, Response Time, and Efficiency. It is essential to analyze these specifications to choose the right servo drive for your needs in industrial applications.