Top Uses of Stainless Steel Woven Wire Mesh for Industrial Applications?

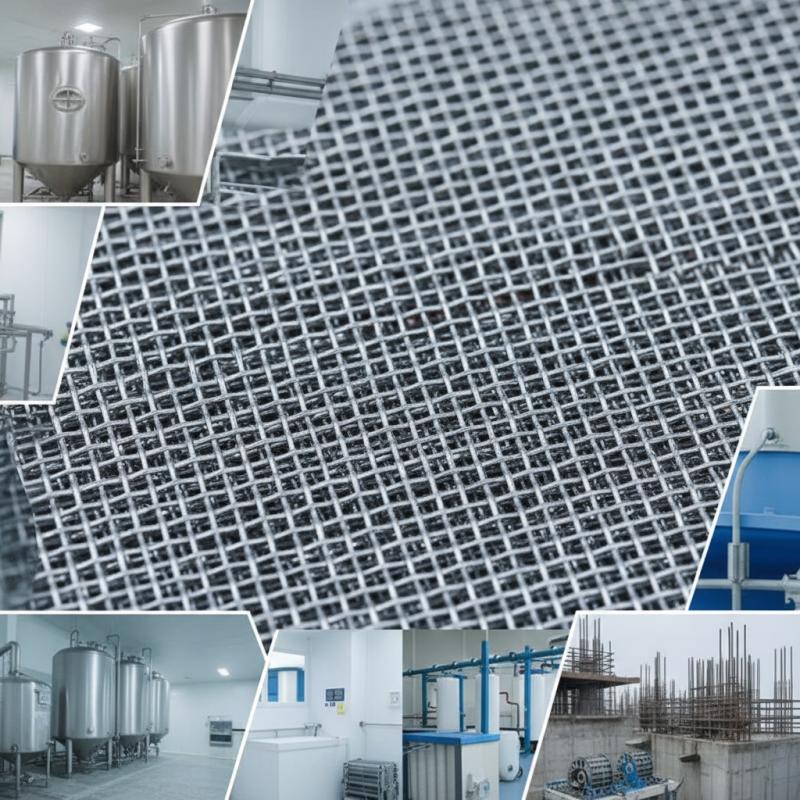

stainless steel woven wire mesh plays a crucial role in various industrial applications. Its durability makes it an ideal choice in many settings. This material withstands harsh conditions and resists corrosion, ensuring longevity.

In the food and pharmaceutical sectors, stainless steel woven wire mesh is invaluable. It helps maintain hygiene standards while allowing for efficient processing. However, even with its many benefits, some industries may overlook its potential.

The versatility of stainless steel woven wire mesh goes beyond these fields. Its use in construction, filtration, and safety applications is expanding. Companies need to explore ways to incorporate this material effectively. They must also consider any limitations it might have in specific environments.

Overview of Stainless Steel Woven Wire Mesh in Industry

Stainless steel woven wire mesh is pivotal in various industrial sectors. Its versatility makes it suitable for filtration, sieving, and even as a protective barrier. The mesh can withstand extreme temperatures and corrosive environments, making it ideal for food processing and chemical industries. It offers a reliable solution where durability and hygiene are required.

In manufacturing processes, stainless steel wire mesh plays a vital role in separating materials. This mesh is used to screen fine particles or aggregate materials in construction. Many industries appreciate its strength and flexibility. However, choosing the right mesh requires careful consideration. Not all applications require the same type or gauge of wire. It is essential to assess specific needs thoroughly to avoid potential pitfalls.

Maintenance is another critical aspect to consider. Regular cleaning prevents buildup and ensures optimal performance. Some find it challenging to keep the mesh clean in certain environments. Investing time in maintenance can enhance its lifespan and functionality. Stainless steel woven wire mesh truly shines when understood and utilized correctly.

Key Properties of Stainless Steel That Benefit Industrial Applications

Stainless steel woven wire mesh offers numerous benefits in industrial applications. Its high corrosion resistance is a significant advantage. This property ensures durability in harsh environments. Industries like food processing rely on this feature. In these settings, hygiene is crucial, and stainless steel excels. The mesh prevents rust and maintains cleanliness.

Another key property is its strength-to-weight ratio. Stainless steel mesh is lightweight yet strong. This makes it ideal for various structural applications. For instance, it can support heavy loads without added weight. However, in some scenarios, its strength may be overestimated. It's essential to assess the specific requirements of each application carefully.

Resistance to temperature changes is also notable. Stainless steel can withstand high and low temperatures. This makes it versatile for diverse industrial uses. Industries like automotive and aerospace benefit greatly. However, not all grades of stainless steel perform equally well. Users should choose carefully based on their needs, reflecting on the specific conditions they will face.

Common Industrial Uses of Stainless Steel Woven Wire Mesh

Stainless steel woven wire mesh is widely used in various industrial applications due to its durability and versatility. One common use is in filtration systems. These systems require strong materials that can withstand high pressure and corrosive environments. The fine mesh structure allows for effective separation of particles from liquids or gases.

Another significant application is in construction. Stainless steel mesh is often employed for safety barriers and reinforcement in concrete. It doesn’t corrode easily, making it ideal for buildings in harsh weather conditions. Additionally, the mesh can enhance drainage and airflow in soil and other materials.

**Tips:** When choosing stainless steel mesh, consider the wire diameter and mesh size. These factors significantly influence strength and filtration efficiency. Also, evaluate the specific application requirements. Not all stainless steel types are suitable for every task. Take time to review materials and their properties thoroughly.

Woven wire mesh is also beneficial in the food processing industry. It aids in the screening of contaminants. However, cleanliness is critical. Regular maintenance ensures hygiene and compliance with health regulations. It’s essential to develop a proper cleaning routine to maintain the mesh's effectiveness over time.

Advantages of Using Stainless Steel Mesh Over Other Materials

Stainless steel woven wire mesh is widely used in various industrial applications. Its strength and durability stand out among materials like plastic and aluminum. Unlike these alternatives, stainless steel does not corrode easily. This resistance makes it a great choice for harsh environments. Industries such as food processing and pharmaceuticals benefit significantly from this feature. They require high levels of hygiene and strength, which stainless steel provides.

Moreover, stainless steel mesh has excellent thermal conductivity. This can be crucial in processes where temperature control matters. In contrast, plastic can deform under heat and aluminum may not withstand certain chemicals. The lifespan of stainless steel products tends to be longer. They are an investment, offering cost savings over time. However, they can be heavier and more expensive initially. Companies need to evaluate their specific needs before choosing the right material. Balancing cost and functionality is vital in the decision-making process.

Maintenance and Durability Considerations for Stainless Steel Mesh

Stainless steel woven wire mesh is widely valued for its durability and longevity in industrial settings. One major consideration is maintenance. Regular cleaning is essential. Dust and debris can accumulate, leading to corrosion. For maintenance, a simple rinse with water may suffice. For tougher grime, a gentle detergent can be effective. It is wise to conduct routine inspections for any signs of wear.

Another aspect is the mesh's resistance to harsh conditions. Stainless steel can withstand high temperatures and chemicals. These properties make it ideal for industries like food processing and filtration. Yet, negligence can lead to unexpected failures. Even stainless steel can corrode over time if not properly maintained. Inspecting welds and joints is crucial. Small issues can escalate quickly.

Durability is a key selling point but remember that perfection is not guaranteed. Environmental factors play a significant role. Humidity can contribute to rust, even in stainless steel. Monitoring these factors helps ensure longevity. A proactive approach to maintenance ultimately pays off. Staying vigilant will extend the life of the mesh. Regular care is a small investment compared to costly repairs.