Top Small DC Motor Applications and Buying Guide for Beginners

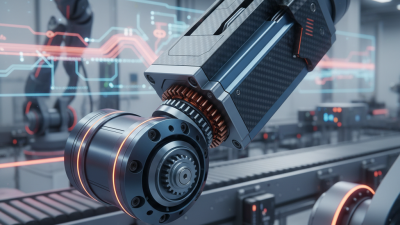

In the ever-evolving landscape of technology, small DC motors have carved out a significant niche across various applications, from robotics to consumer electronics. Renowned industry expert Dr. Jane Thompson emphasizes their versatility, stating, "Small DC motors are the heart of countless devices, providing the necessary power and precision in compact designs." As these motors continue to proliferate in both commercial and DIY projects, understanding their applications and functionality has never been more crucial for enthusiasts and beginners alike.

In this guide, we will explore the top applications of small DC motors and provide essential insights for prospective buyers. From driving miniature vehicles to powering automated systems in home appliances, the reliability and efficiency of small DC motors make them an ideal choice for innovators and hobbyists. Whether you're looking to start a new project or enhance an existing one, familiarizing yourself with these motors can unlock a world of possibilities in your engineering pursuits.

Overview of Small DC Motors and Their Importance

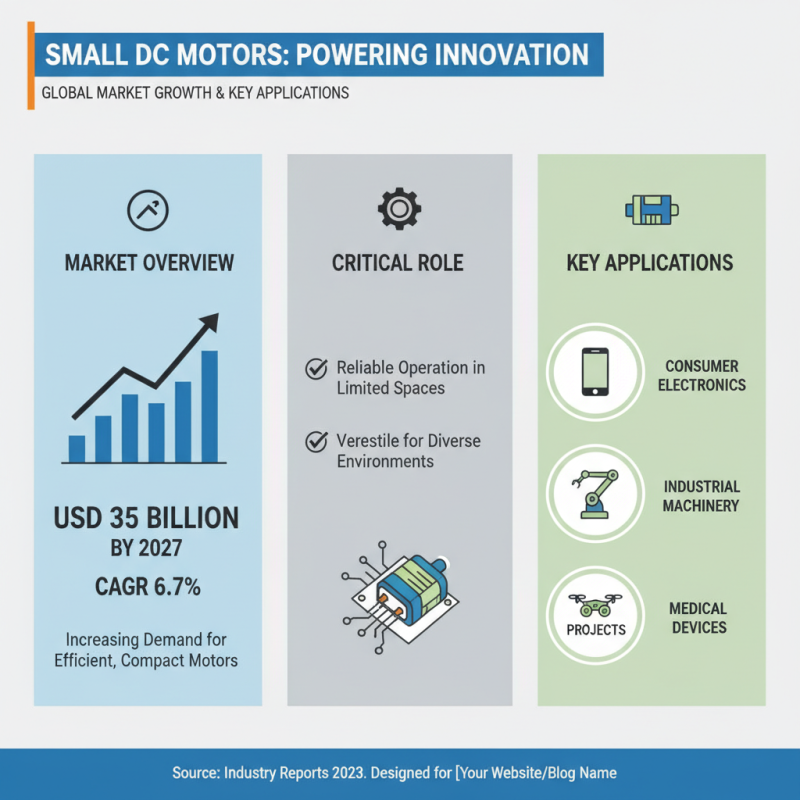

Small DC motors are pivotal components in a wide array of applications, playing a critical role in the functionality of various devices from consumer electronics to industrial machinery. Recent industry reports indicate that the global market for small DC motors is projected to reach USD 35 billion by 2027, growing at a compound annual growth rate (CAGR) of 6.7%. This growth underscores the increasing demand for efficient and compact motors that provide reliable operation in limited spaces. Their versatility allows them to operate in diverse environments, making them essential for both hobbyist projects and large-scale industrial applications.

In addition to their growing market demand, small DC motors are valued for their easy integration and adaptability. They can be found in applications such as robotics, automotive systems, and household appliances. According to a study conducted by the International Electrotechnical Commission, small DC motors account for approximately 60% of all motor sales globally, illustrating their dominance in electric motor technology. Their importance lies not only in providing motion but also in enabling precise control of speed and torque, which is crucial for the advancement of automated technologies and smart devices. As industries continue to innovate, the role of small DC motors remains vital in driving efficiency and enhancing user experience across products.

Common Applications of Small DC Motors in Various Industries

Small DC motors play a vital role across various industries due to their compact size, efficiency, and ease of use. In the robotics sector, these motors are often utilized in actuators for robotic arms and small vehicles, enabling precise movement and control. According to a report from the International Federation of Robotics, the market for robotics in manufacturing is projected to grow by 10% annually, highlighting the increasing demand for reliable and efficient actuation technologies. Additionally, in the consumer electronics industry, small DC motors are commonly found in devices such as handheld vacuums and electronic toys, where they provide the necessary power in confined spaces.

In medical devices, small DC motors serve critical functions in applications ranging from portable pumps to surgical tools. A study by the Medical Device Manufacturers Association revealed that the medical device sector is expected to reach $208 billion by 2024, indicating a substantial opportunity for the integration of efficient motor technologies. These motors help ensure precision in operation, which is paramount in a field where accuracy can impact patient outcomes significantly.

Tips: When selecting a small DC motor, consider factors such as torque, speed, and power requirements specific to your application. It’s also important to evaluate the motor’s lifespan and reliability based on industry standards, which can save costs in maintenance and replacement over time. For beginners, purchasing a few different types for prototyping can aid in understanding the various performance characteristics before committing to a specific type for larger projects.

Top Small DC Motor Applications and Buying Guide for Beginners

| Application | Industry | Typical Voltage Range (V) | Speed (RPM) | Torque (mNm) |

|---|---|---|---|---|

| Robotics | Manufacturing | 6 - 12 | 2000 - 5000 | 10 - 50 |

| Home Appliances | Consumer Electronics | 4.5 - 12 | 1500 - 3000 | 5 - 20 |

| Medical Devices | Healthcare | 6 - 15 | 500 - 3000 | 10 - 40 |

| Toys | Entertainment | 3 - 12 | 1000 - 5000 | 2 - 15 |

| Automotive | Transportation | 12 - 24 | 3000 - 10000 | 20 - 100 |

Factors to Consider When Buying a Small DC Motor

When purchasing a small DC motor, several key factors should be taken into account to ensure you select the right component for your project.

First and foremost, you should consider the motor's voltage and current specifications. Understanding the power supply available for your application is crucial, as mismatched voltage can lead to inefficiency or damage.

Also, the required torque and speed of the motor should align with the demands of your project; these specifications directly impact performance and functionality.

Another important aspect is the motor’s size and weight, especially if space is at a premium in your design. Evaluate the physical dimensions to ensure it fits well within your project's constraints. Additionally, the type of gearing involved can play a significant role in the motor's output characteristics, as it can affect torque and speed ratios.

Lastly, consider the durability and environmental ratings of the motor, particularly if it will be used in harsh conditions. Selecting a motor with the right specifications and features will ultimately lead to a more successful project outcome.

Types of Small DC Motors and Their Specific Uses

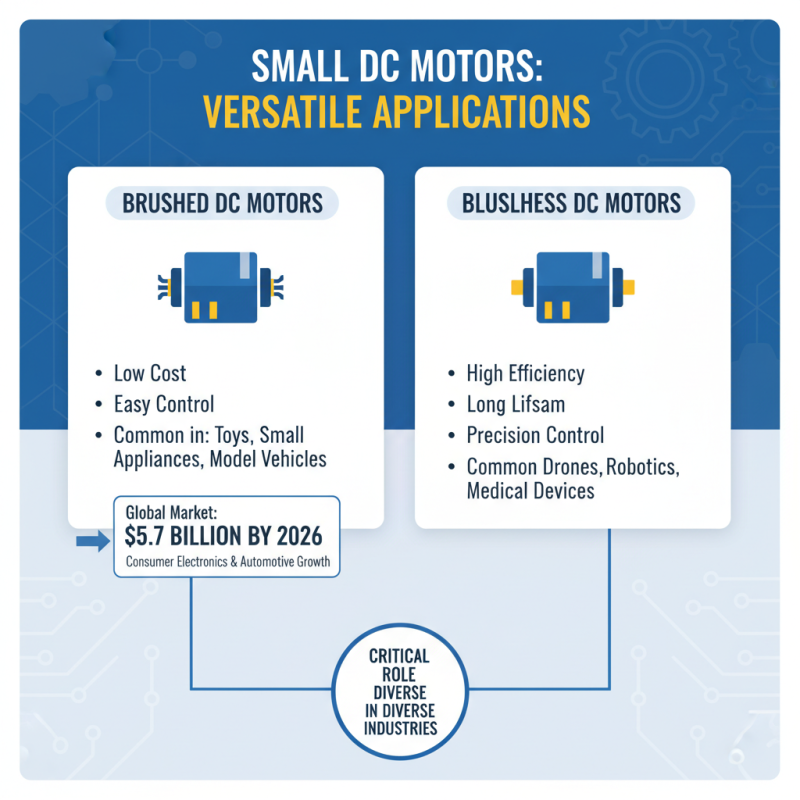

Small DC motors are versatile components that play a critical role in various applications across multiple industries. These motors are generally classified into brushed and brushless types, each having specific advantages suited to different uses. Brushed motors are commonly favored in simple applications such as toys, small appliances, and model vehicles due to their low cost and ease of control. According to a recent industry report, the global brushed DC motor market is projected to reach approximately $5.7 billion by 2026, driven largely by increases in consumer electronics and automotive applications.

Conversely, brushless DC motors are preferred for applications requiring higher efficiency and longevity, such as in robotics, drones, and electric vehicles. Their design minimizes wear and tear, leading to reduced maintenance needs and longer operational life. A market analysis indicates that the brushless DC motor sector will experience significant growth, anticipating a compound annual growth rate (CAGR) of around 8.5% from 2021 to 2028, as industries continue to seek more sustainable and efficient energy solutions. Understanding the differences in types and their specific applications is essential for beginners looking to navigate the diverse landscape of small DC motors effectively.

Tips for Beginners on Installing and Maintaining Small DC Motors

Installing and maintaining small DC motors can be a straightforward process if approached with the right knowledge and tools. For beginners, the first step in installation is to carefully read the motor's specifications and ensure compatibility with your project requirements. Pay attention to factors such as voltage, current, and torque specifications. Secure mounting is crucial; use appropriate brackets and screws to ensure that the motor remains stable during operation. Additionally, wiring should be done correctly to avoid shorts, with careful attention paid to polarity if the motor has directional features. Utilizing connectors can simplify wiring and maintenance down the line.

Once your motor is installed, regular maintenance will ensure optimal performance and longevity. Keeping the motor clean is essential; dust and debris can affect its efficiency. It is advisable to check the wiring connections periodically for any signs of wear or corrosion. If your motor has bearings, lubricate them according to the manufacturer’s recommendations to reduce friction and wear. Additionally, monitoring the motor’s temperature during operation can provide insights into its health—overheating might indicate a problem that requires immediate attention. By following these beginner-friendly tips, you can effectively install and maintain small DC motors, ensuring they remain functional and reliable for your applications.

Related Posts

-

5 Best Ways to Optimize Motor Power for Industrial Efficiency

-

Understanding the Advantages of AC Servo Drives in Modern Automation Solutions

-

Top Strategies for Maximizing Performance with Best AC Servo Drives

-

How to Choose the Best High Torque Servo for Your Applications in 2025

-

7 Essential Tips for Maximizing Performance with AC Servo Motors

-

Overcoming Common Challenges with Servo Motors: A Deep Dive into Performance and Reliability Issues