7 Reasons Why Your Factory Needs an AC Servo Motor Today

In today's manufacturing landscape, the importance of precision and efficiency is paramount, and this is where the ac servo motor shines. According to a recent report by MarketsandMarkets, the global servo motors and drives market is projected to reach $11.54 billion by 2025, growing at a CAGR of 6.9% from 2020. This surge is driven by the rising need for automation and enhanced control in various industrial applications. AC servo motors, known for their high efficiency and reliability, are essential for factories seeking to improve production quality and reduce operational costs. With the ability to provide precise position control and a fast response to dynamic inputs, these motors are not just an alternative—they are becoming a necessity for manufacturers aiming to stay competitive in a rapidly evolving market. The integration of ac servo motors can significantly impact overall productivity, making them a vital consideration for any forward-thinking factory.

The Rise of AC Servo Motors: Industry Statistics Driving Factory Automation

The landscape of industrial automation is rapidly evolving, with AC servo motors emerging as a vital component driving efficiencies in factories today. According to industry statistics, the global servo drive market is expected to witness significant growth, bolstered by increased automation initiatives across diverse sectors. This trend indicates a robust demand for advanced control solutions that enhance precision and reliability in manufacturing environments.

In 2023, the digital servo motors and drives market was valued at approximately USD 8.5 billion, with projections showing a steady growth rate of 6.7% through 2032. Such figures highlight the importance of investing in AC servo technology, as it not only supports improved operational performance but also aligns with broader market trends towards energy efficiency and sustainability.

Tip 1: When considering the transition to AC servo motors, evaluate your specific automation needs and potential ROI to ensure alignment with your operational goals.

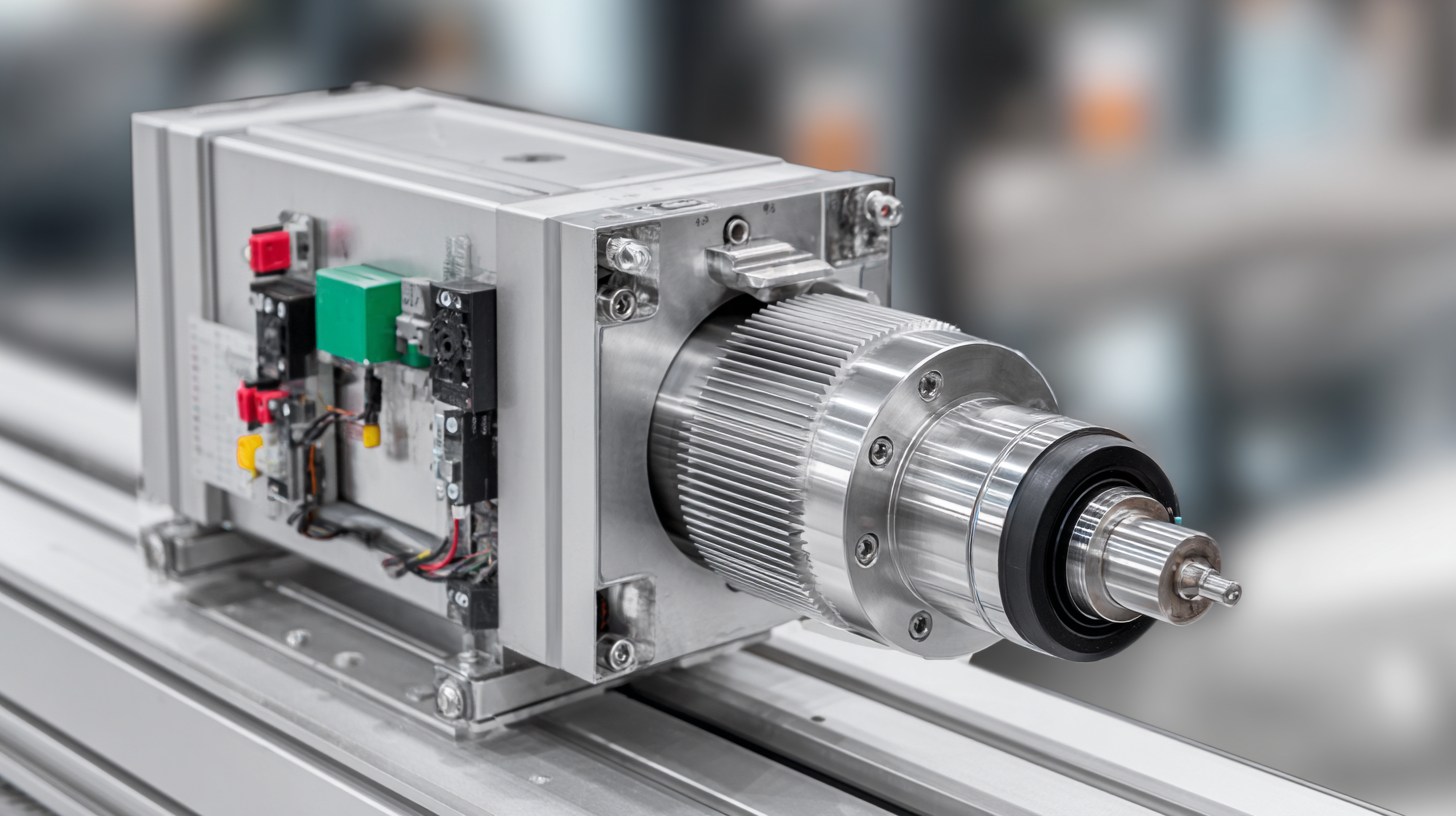

Tip 2: Stay informed about innovations in servo technology, as advancements such as integrated servo motors can provide additional benefits in terms of space savings and ease of implementation.

Tip 3: Engage with industry experts to assess the best options for your factory, as tailored solutions can lead to optimal performance and greater competitiveness in the market.

Enhanced Precision: How AC Servo Motors Improve Manufacturing Accuracy by Over 20%

In the ever-evolving landscape of manufacturing, the demand for precision has never been greater. AC servo motors stand at the forefront of this revolution, injecting remarkable accuracy into production processes. According to a report by the International Federation of Robotics, manufacturing systems that integrate AC servo technology have been shown to enhance operational precision by over 20%. This is not just a marginal improvement; it translates into significant reductions in defects and waste, ultimately yielding higher quality products and increased customer satisfaction.

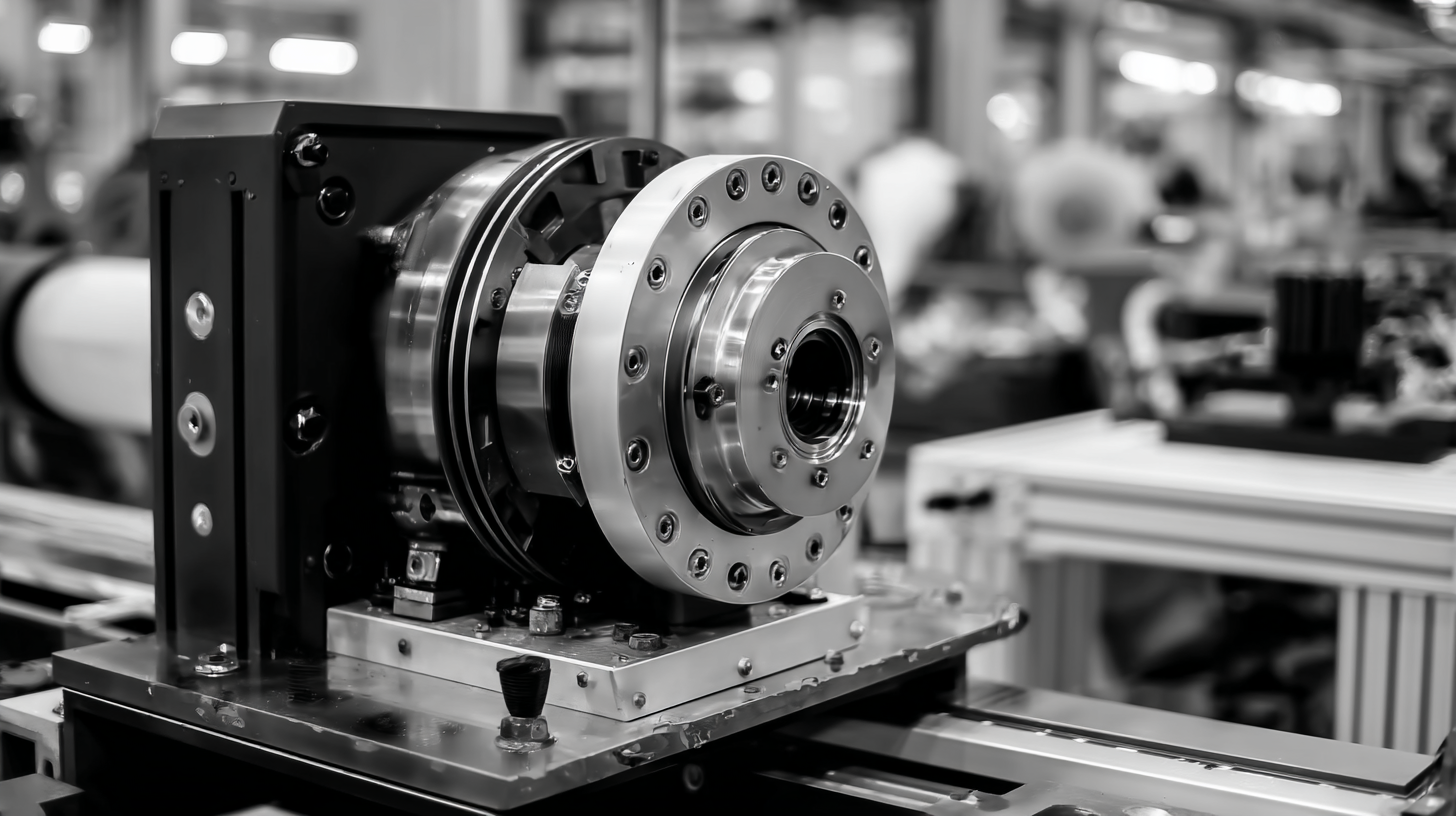

The remarkable accuracy of AC servo motors arises from their precise feedback control systems, which allow for real-time adjustments and optimal performance. A study published in the Journal of Manufacturing Science and Engineering highlights that the closed-loop control feature of AC servo motors enables manufacturers to achieve a tolerance level as tight as 0.01mm. By employing these advanced motors, factories can optimize processes that require rapid acceleration and deceleration, ensuring that every component is manufactured to exact specifications. As industries strive for leaner operations, the integration of AC servo motors is proving to be essential for maintaining a competitive edge in an increasingly demanding market.

Energy Efficiency: Achieving Up to 30% Reduced Energy Consumption with AC Servo Systems

In today's manufacturing landscape, the push for energy efficiency has never been more critical. AC servo motors are at the forefront of this transformation, offering remarkable energy savings of up to 30% compared to traditional systems. Research indicates that the global market for AC servo motors and drives is projected to grow significantly, with estimates suggesting a valuation of USD 15.2 billion in 2024 and a promising growth rate of 6.6% from 2025 to 2034. This growth reflects an increasing adoption of these advanced motors across various applications, driven by their capability to enhance operational efficiency and reduce energy waste.

Moreover, the energy-efficient motor market is rapidly evolving, with a wealth of options categorized by efficiency levels such as IE1 to IE5 and various motor types including AC and DC. The focus is shifting towards higher efficiency ratings, particularly as industries strive to comply with stringent energy regulations and minimize their carbon footprint. For instance, traction motors used in electric vehicles are being analyzed extensively to maximize mechanical efficiency, showcasing a broader trend of prioritizing energy conservation for sustainable development. Embracing AC servo technology not only meets these industry needs but also positions factories for a more energy-efficient future.

Increased Speed and Responsiveness: Boosting Production Rates by 50% with Servo Technology

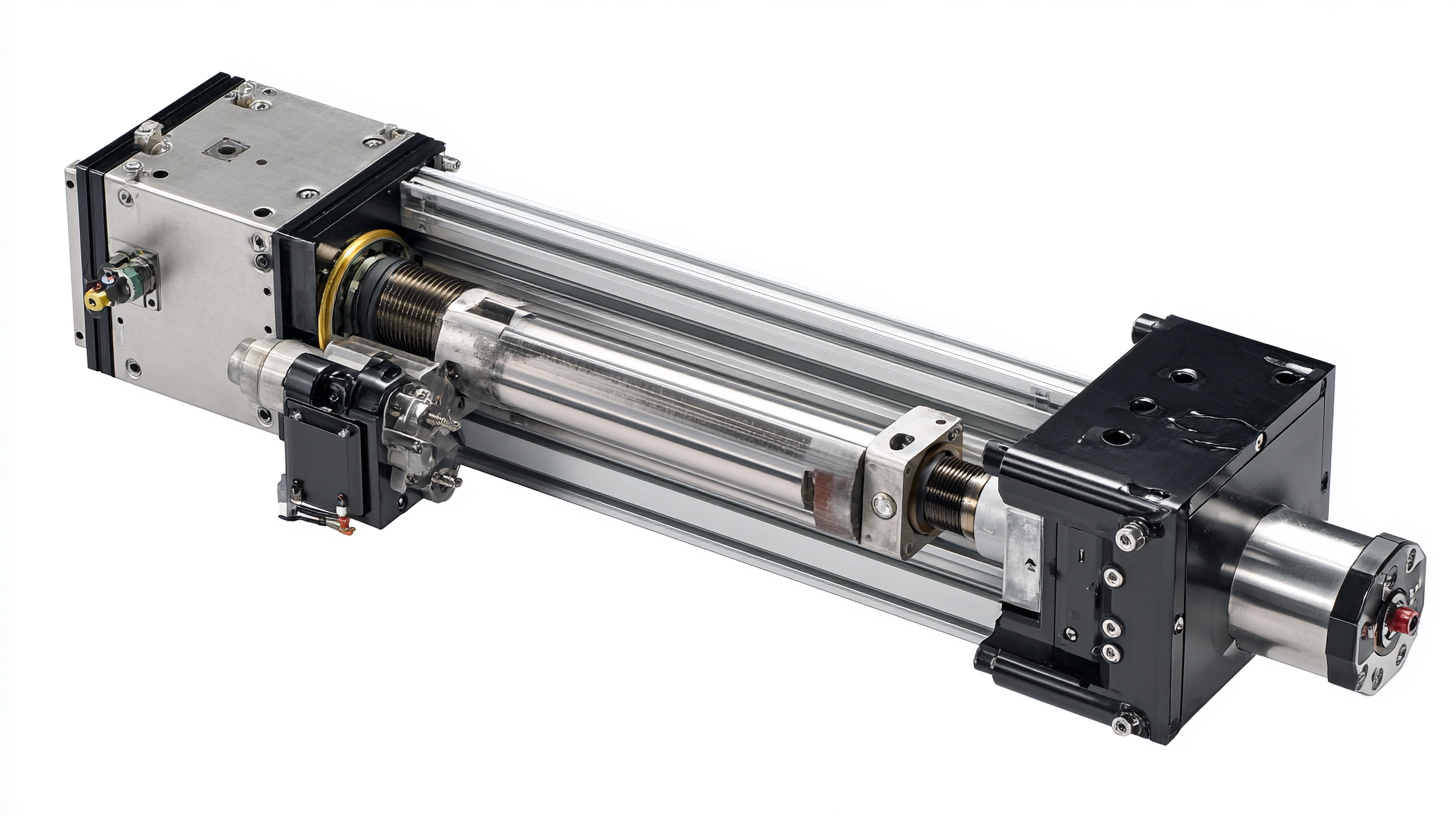

In today’s fast-paced manufacturing environment, the need for speed and responsiveness is paramount. AC servo motors have emerged as a transformative technology that can enhance production rates significantly—up to 50% in some cases. Unlike traditional motors, servo motors provide precise control over speed and position. This level of precision allows factories to execute operations more efficiently and reduce cycle times, thereby maximizing throughput. As a result, companies leveraging this technology can respond more quickly to market demands, making them more competitive.

The integration of AC servo motors not only boosts speed but also enhances system responsiveness. With real-time feedback mechanisms, these motors can adjust their performance instantaneously to changing production requirements. This dynamic capability reduces downtime and minimizes challenges associated with load variations. Consequently, manufacturers adopting servo technology can optimize their processes, maintain consistent product quality, and improve overall operational efficiency. The impact on production rates is remarkable, positioning factories that invest in AC servo motors to meet customer expectations and adapt swiftly to industry trends.

Minimized Maintenance Costs: How AC Servo Motors Reduce Downtime by 40% in Manufacturing Operations

In today’s fast-paced manufacturing environment, minimizing downtime is crucial for maintaining productivity and reducing costs. Implementing AC servo motors into your operations can lead to a significant reduction in maintenance costs—up to 40%—which directly translates to less time lost during production. These motors are designed for high efficiency and reliability, ensuring that machines run smoother and require less frequent repairs.

One of the key advantages of AC servo motors is their ability to self-diagnose potential issues before they escalate into serious problems. This proactive approach not only enhances performance but also allows maintenance teams to plan and execute repairs during scheduled downtimes, further reducing the impact on production.

Tip: Regularly update your maintenance schedules based on the performance data from your AC servo motors. This allows for timely interventions and can help prevent unexpected breakdowns. Moreover, consider training your staff on the specifics of AC servo technology to help them identify minor issues early on.

Tip: Always keep spare parts on hand for your AC servo systems. This simple step can significantly cut down repair time, ensuring that your factory remains operational even when unforeseen issues arise. By integrating these strategies, your factory can fully leverage the benefits of AC servo motors, enhancing both efficiency and sustainability in your manufacturing processes.