Overcoming Common Challenges with Servo Motors: A Deep Dive into Performance and Reliability Issues

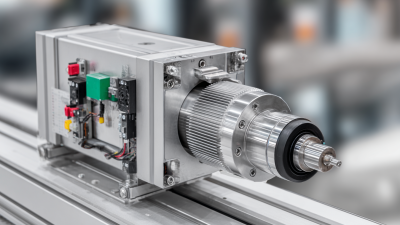

In today's rapidly advancing automation landscape, servo motors have emerged as critical components in various industrial applications, from robotics to CNC machinery. According to a recent report by MarketsandMarkets, the global servo motor market is projected to reach $16.3 billion by 2025, driven by the increasing demand for precision control in automated systems. However, as the utilization of servo motors expands, so do the challenges associated with their performance and reliability. Common issues such as overheating, inadequate feedback mechanisms, and noise can impede the operational efficiency of these systems. This blog aims to provide a comprehensive tutorial on overcoming these challenges, ensuring that users can harness the full potential of servo motors while minimizing downtime and maximizing productivity.

Identifying Common Performance Issues in Servo Motors

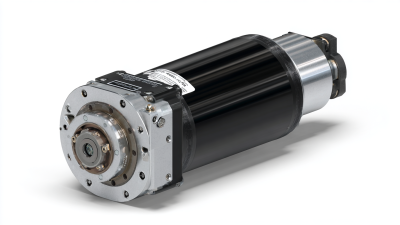

Servo motors are essential components in a wide range of industrial applications, known for their precision and performance. However, common performance issues can hinder their effectiveness. One significant challenge is the occurrence of overshooting during the motion control process. This happens when the motor exceeds the desired position before settling down, potentially damaging the equipment or leading to inaccuracies in operations. Tuning the control loop parameters and implementing advanced feedback mechanisms can help mitigate this problem.

Another frequent issue is inconsistent torque output, which can be attributed to insufficient power supply or improper calibration. Variability in torque can affect the responsiveness and stability of the system, resulting in erratic movements. Ensuring that the servo motor receives adequate power and regularly checking for wear in components can enhance performance consistency. Additionally, monitoring environmental factors, such as temperature and humidity, can play a crucial role in maintaining torque reliability and ensuring that the servo systems perform optimally in various conditions.

Overcoming Common Challenges with Servo Motors: A Deep Dive into Performance and Reliability Issues

| Issue | Description | Common Causes | Potential Solutions |

|---|---|---|---|

| Inadequate Torque | Insufficient output torque for application needs. | Wrong motor selection, high load demands. | Choose a motor with a higher torque rating. |

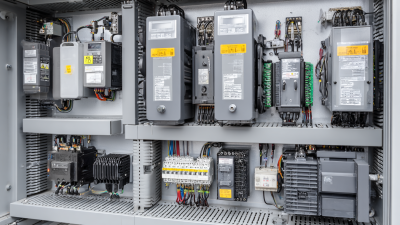

| Signal Noise | Interference in control signals leads to erratic motor behavior. | Poor cable shielding, electromagnetic interference. | Use shielded cables and proper grounding techniques. |

| Overheating | Motor temperature exceeds optimal operating range. | Continuous high load, inadequate cooling. | Implement cooling methods and derate motor. |

| Positioning Errors | Incorrect positioning of the servo motor. | Feedback loop issues, mechanical binding. | Check feedback components and mechanical assemblies. |

| Vibration | Excessive vibrations affecting performance. | Unbalanced load, improper mounting. | Balance load and ensure secure mounting. |

Understanding Reliability Challenges in Servo Motor Applications

In the realm of industrial automation and robotics, servo motors play a crucial role in achieving precision and control. However, understanding the reliability challenges associated with these components is essential for optimizing their performance in various applications. One significant issue is thermal management; servo motors can generate substantial heat during operation, which, if not properly dissipated, may lead to premature failure. This requires effective cooling systems to ensure that motors operate within their designated temperature ranges.

Another critical reliability challenge is wear and tear caused by continuous motion and load. Over time, gears, bearings, and other moving parts can degrade, resulting in a decline in performance. Regular maintenance and timely inspections become imperative to identify potential failures before they escalate. Furthermore, environmental factors such as humidity, dust, and corrosive substances may also impact the longevity of servo motors. By understanding these reliability challenges, engineers can implement targeted strategies to enhance the durability and efficiency of servo motors in their specific applications.

Mitigating Controller and Feedback Loop Errors in Servo Systems

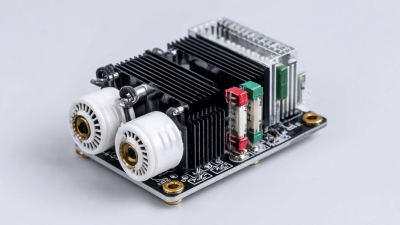

Servo motors play a crucial role in various automation applications, but they are not without their challenges. One of the most significant hurdles engineers face is the management of controller and feedback loop errors. These errors can lead to inadequate system performance and affect the overall reliability of the servo system. A well-tuned controller is essential for translating desired commands into precise motor actions, while an accurate feedback loop ensures that the system can respond to any discrepancies in position or speed.

To mitigate these errors, implementing advanced control strategies is vital. Techniques such as PID (Proportional-Integral-Derivative) control can help fine-tune the response of the servo system, reducing overshoot and settling time. Additionally, incorporating real-time monitoring and adaptive control algorithms can allow systems to adjust to changing conditions dynamically, minimizing the impact of environmental variables. Regular calibration and maintenance also play a significant role in ensuring feedback devices, such as encoders, are functioning correctly, further enhancing the accuracy of the entire servo system. By addressing these critical aspects, engineers can significantly improve the performance and reliability of servo motors in their applications.

Best Practices for Maintaining Servo Motor Efficiency and Lifespan

To maintain the efficiency and lifespan of servo motors, it’s crucial to adopt best practices tailored to their unique operating conditions. Regular maintenance routines should include thorough inspections for signs of wear and tear, particularly in the bearings, gears, and electrical connections. Lubrication of moving parts not only minimizes friction but also helps prevent overheating, a common issue that can significantly reduce a motor’s lifespan. Monitoring operating temperatures and vibration levels can provide early warnings of potential performance issues, allowing for timely interventions.

Moreover, ensuring proper alignment during installation can greatly enhance motor performance. Misalignment often leads to excessive wear and energy losses. Implementing a controlled environment, free from dust and corrosive substances, can also improve reliability. Additionally, utilizing high-quality components in both the motor and its control systems contributes significantly to overall robustness. Educating operational staff on the significance of these practices will empower them to recognize and address minor issues before they escalate into major problems, ultimately extending the useful life of the servo motors.

Innovative Solutions to Enhance Servo Motor Performance and Reliability

When it comes to enhancing the performance and reliability of servo motors, innovative solutions have become pivotal amidst the challenges the industry faces. According to the "Global Servo Motor Market Trends" report by ResearchAndMarkets, the servo motor market is projected to grow from USD 10.12 billion in 2021 to USD 17.77 billion by 2028, at a CAGR of 8.5%. This growth underscores the increasing demand for high-performance servo motors across various sectors, including robotics, aerospace, and manufacturing.

One strategy to improve the reliability of servo motors involves the implementation of advanced feedback mechanisms. Utilizing high-resolution encoders can significantly increase precision in control, which is crucial for applications requiring utmost accuracy. Furthermore, integrating temperature and vibration monitoring systems can preempt potential failures, as highlighted in the IEEE Transactions on Industrial Electronics, which estimates that predictive maintenance techniques can reduce downtime by up to 30%.

Additionally, incorporating machine learning algorithms to fine-tune performance parameters dynamically is gaining traction. These algorithms can analyze operational data in real-time, allowing for proactive adjustments that enhance efficiency and longevity. As reported by the International Journal of Advanced Manufacturing Technology, systems employing such smart technologies have shown a 15% improvement in operational efficiency and a 20% reduction in energy consumption, illustrating the impact of innovation on servo motor reliability.

Related Posts

-

7 Reasons Why Your Factory Needs an AC Servo Motor Today

-

Future Trends in Technology 2025 How to Choose the Best Servo Amplifier for Your Applications

-

Exploring 2025 Tech Trends: How to Choose the Best Frameless Motor for Your Business Needs

-

Innovative Solutions for Achieving Maximum Efficiency with Best DC Servo Motors

-

Top Strategies for Maximizing Performance with Best AC Servo Drives

-

Future Innovations in Servo Motor Drivers Shaping Global Industry Trends in 2025