Innovative Solutions for Achieving Maximum Efficiency with Best DC Servo Motors

In today's highly competitive manufacturing landscape, achieving maximum efficiency is paramount, and DC servo motors have emerged as a pivotal solution in this pursuit. According to a recent report from MarketsandMarkets, the global servo motor market is projected to reach $11.39 billion by 2026, growing at a CAGR of 7.4% between 2021 and 2026. This growth underscores the increasing reliance on advanced motion control technologies, particularly DC servo motors, which are favored for their precision, speed, and reliability across various applications including robotics, automation, and aerospace.

As industries strive to enhance productivity and reduce operational costs, integrating DC servo motors has proven essential. This blog will explore innovative solutions and case studies that highlight the transformative impact of DC servo motors in diverse sectors, providing compelling reasons to harness their potential for achieving operational excellence.

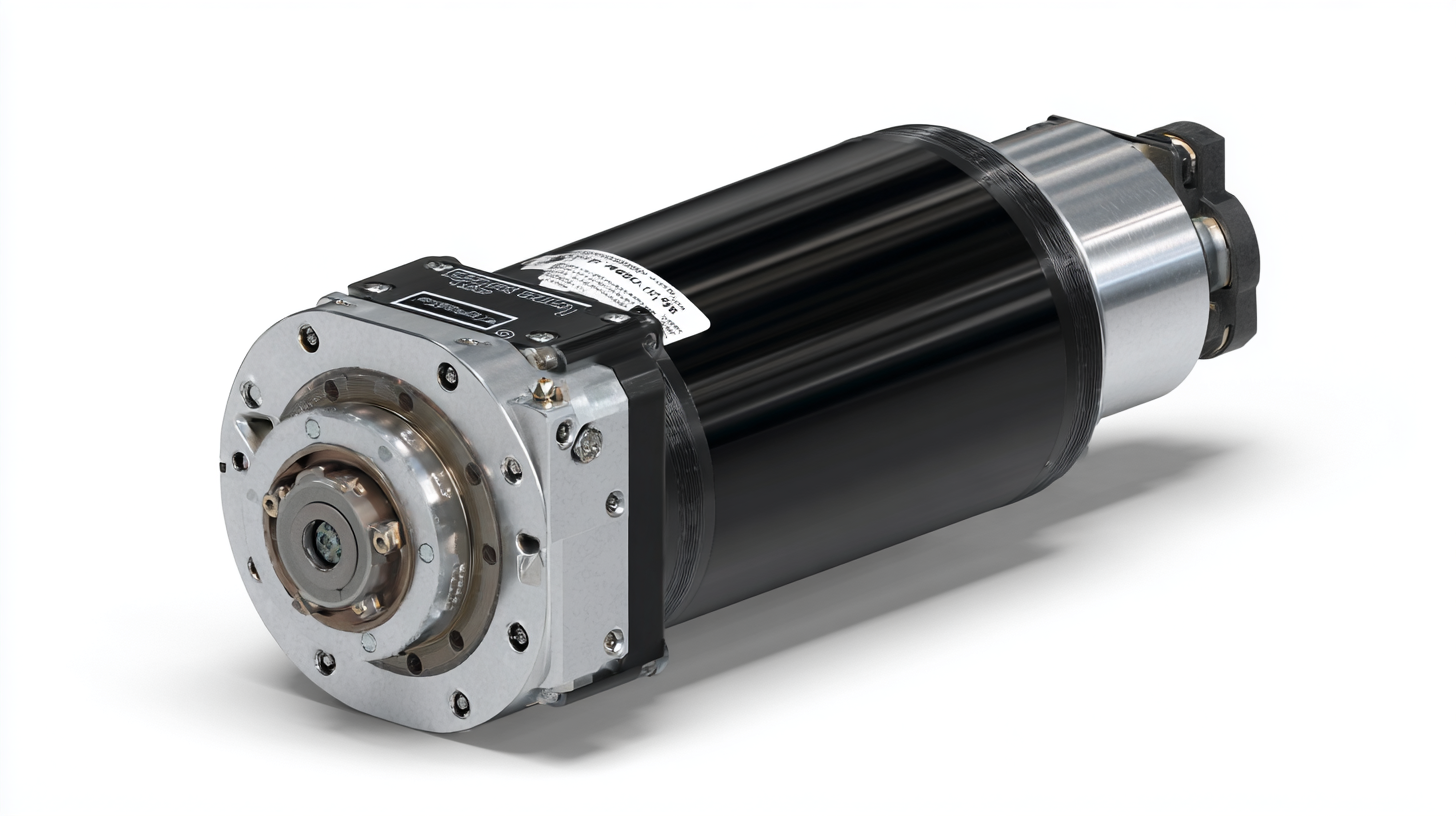

Understanding the Importance of DC Servo Motors in Modern Industries

In modern industries,

the significance of DC servo motors cannot be overstated.

These motors play an essential role in automation and precision applications, driving advancements

in robotics, CNC machinery, and conveyor systems. Their ability to deliver consistent performance

and precise control makes them a preferred choice for many applications. As industries strive for

maximum efficiency, understanding the

functionality and benefits of DC servo motors becomes crucial.

One tip for optimizing the use of DC servo motors is to select the right motor size and specifications

tailored to your application. Overloading or underutilizing a motor can lead to inefficiencies and

increased wear. Additionally, ensure that the motor is properly integrated with the control system

to leverage features like feedback and real-time adjustments, which enhance performance and accuracy.

Another key tip is to conduct

regular maintenance and monitoring.

Keeping motors clean and lubricated not only extends their lifespan but also ensures consistent performance.

Implementing a predictive maintenance strategy can help identify issues before they escalate, minimizing

downtime and operational disruptions. By focusing on these aspects, industries can harness the full

potential of DC servo motors, driving innovation and efficiency in their processes.

Key Features of High-Performance DC Servo Motors for Enhanced Productivity

When it comes to maximizing productivity in various industrial applications, high-performance DC servo motors are at the forefront. These motors offer superior control and precision, which are critical in automation, robotics, and manufacturing processes. According to a recent report by Allied Market Research, the global DC servo motor market is projected to reach $2.8 billion by 2025, driven by the demand for high efficiency and reliability in automation.

One of the key features that sets high-performance DC servo motors apart is their advanced feedback systems. These systems enable real-time monitoring and adjustment, ensuring optimal performance under various conditions. Additionally, many modern DC servo motors incorporate brushless designs, which not only minimize maintenance but also enhance energy efficiency. Research indicates that brushless motors can improve overall energy savings by up to 20% compared to traditional brushed motors, making them an ideal choice for energy-conscious operations.

Furthermore, the integration of smart technologies in DC servo motors provides invaluable data analytics capabilities. By utilizing IoT-enabled devices, companies can monitor motor performance remotely, significantly reducing downtime through predictive maintenance. A study by MarketsandMarkets highlights that businesses utilizing smart motors can experience a 30% increase in operational efficiency, highlighting the essential role of these advanced features in driving productivity.

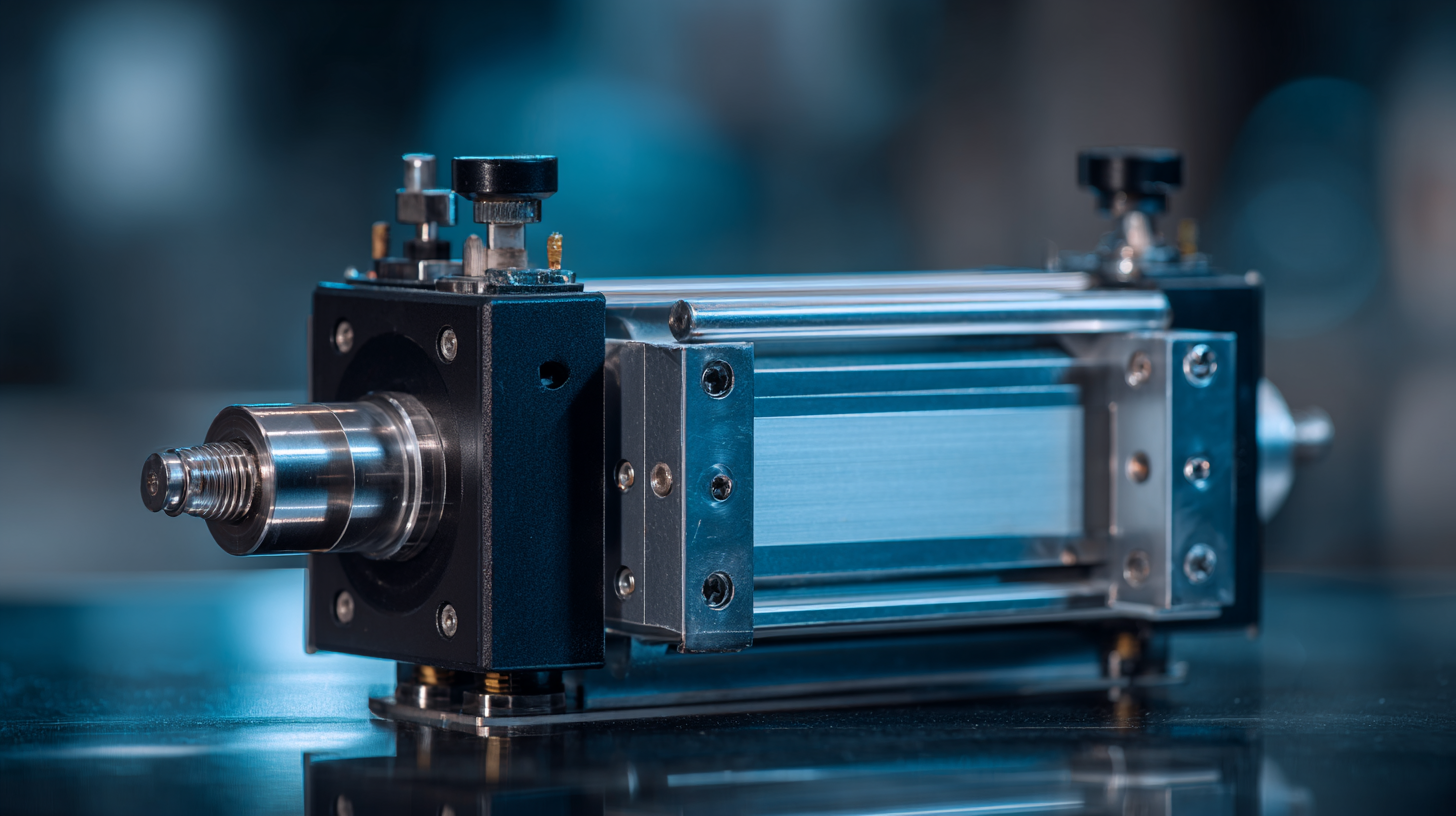

Comparative Analysis: Traditional Motors vs. DC Servo Motors in Efficiency

When comparing traditional motors to DC servo motors, the most striking difference lies in their efficiency. Traditional motors often rely on simple induction principles and can suffer from significant energy losses due to heat dissipation and mechanical friction. In contrast, DC servo motors utilize advanced feedback systems and precise control mechanisms, which optimize their performance and minimize wasted energy. This makes them an ideal choice for applications demanding high precision and speed, such as robotics and automated manufacturing processes.

The adaptability of DC servo motors also further enhances their efficiency. Unlike traditional motors, which typically operate at a fixed speed, DC servo motors can adjust their speed and torque in real-time based on the demands of the application. This dynamic response not only improves the overall energy consumption but also extends the lifespan of the motor, reducing maintenance costs. Consequently, industries are increasingly recognizing the benefits of integrating DC servo motors into their operations, as they not only provide better performance but also align with sustainability goals by lowering their carbon footprint.

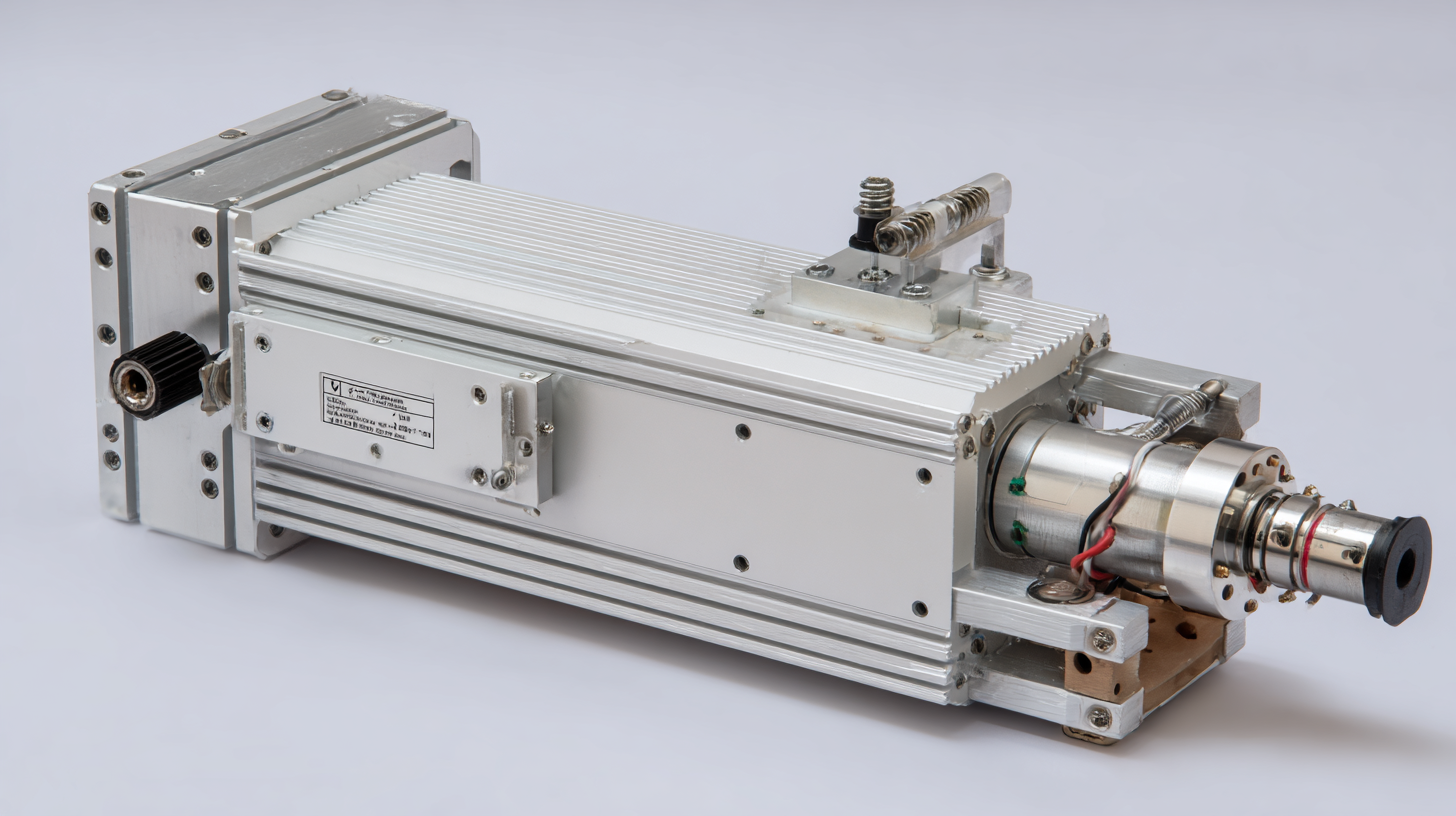

Real-World Applications: DC Servo Motors Driving Innovation Across Sectors

In recent years, DC servo motors have emerged as vital components driving innovation across various sectors, from manufacturing to healthcare. According to a report by Research and Markets, the global servo motor market is expected to grow from $7.6 billion in 2021 to $12.4 billion by 2026, reflecting a compound annual growth rate (CAGR) of 10.5%. This growth underscores the increasing reliance on automation and precise control, characteristics that DC servo motors deliver efficiently.

In the manufacturing industry, DC servo motors are integral to robotics and automated assembly lines. A case study from the International Federation of Robotics highlights that manufacturers utilizing servo motors have seen productivity gains of over 20%, thanks to their ability to enhance precision and reduce cycle times. Furthermore, the healthcare sector is leveraging DC servo motor technology in medical devices such as robotic surgical systems and automated drug dispensing units, resulting in improved patient outcomes and reduced operational costs. As various industries adopt these advanced systems, the role of DC servo motors continues to expand, showcasing their fundamental importance in driving modern innovation.

Efficiency of DC Servo Motors Across Various Industries

Best Practices for Selecting the Right DC Servo Motor for Your Business Needs

Selecting the right DC servo motor is crucial for maximizing efficiency in various applications. According to a report by MarketsandMarkets, the global market for DC servo motors is projected to reach $3.5 billion by 2025, growing at a CAGR of 6.2%. These figures underscore the importance of investing in quality motors that align with specific business requirements. When evaluating options, consider factors such as torque, speed, form factor, and control systems. For instance, higher torque ratings can enhance performance in demanding applications, while compact designs may be necessary for space-constrained environments.

Additionally, it is essential to assess the motor's compatibility with your existing systems. Industry research suggests that over 70% of production downtime can be attributed to equipment failure, which underscores the significance of proper selection and integration. When choosing a DC servo motor, businesses should also prioritize features like feedback mechanisms and customization options, which can significantly improve operational precision. By applying these best practices, companies can ensure that they select a motor that not only meets their immediate needs but also supports future growth and innovation.