Top Strategies for Maximizing Performance with Best AC Servo Drives

In today's highly competitive industrial landscape, the demand for precision and efficiency is at an all-time high, making the role of AC servo drives critical in achieving optimal performance. According to a recent market report from Research and Markets, the global AC servo market is projected to reach $7.1 billion by 2026, growing at a CAGR of 6.5%. This growth underscores the importance of advanced motion control technologies in manufacturing processes. By utilizing the best AC servo drives, businesses can enhance their automation capabilities, reduce energy consumption, and increase productivity. As we explore the top strategies for maximizing performance with AC servo drives, understanding the operational benefits, integration techniques, and the latest technological advancements will be essential for leveraging their full potential in various applications.

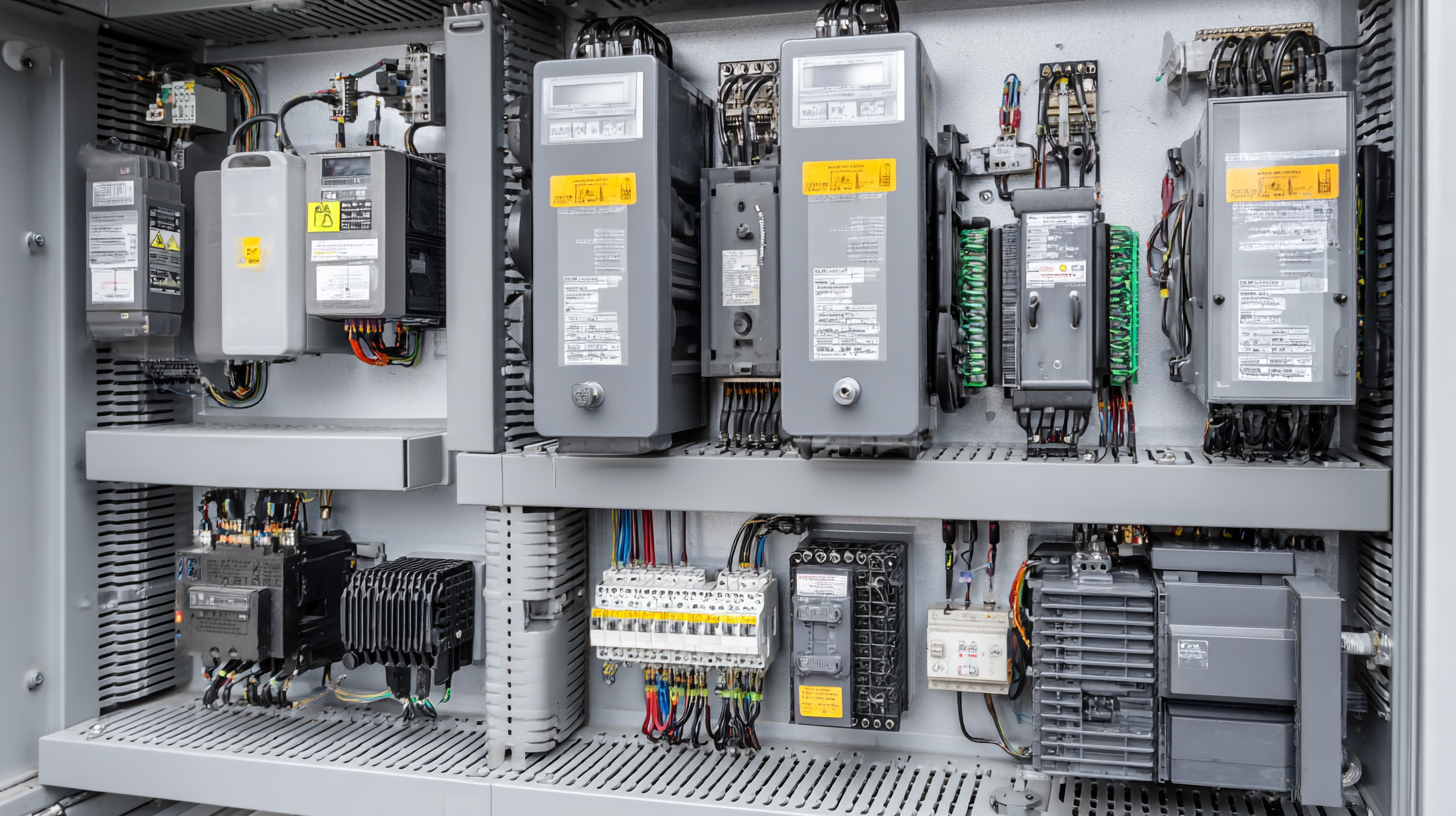

Key Features of AC Servo Drives and Their Applications

AC servo drives have become an essential component in modern automation and robotics, primarily due to their high performance and efficiency. A report by MarketsandMarkets predicts that the global AC servo drive market will grow from $9.2 billion in 2021 to $14.7 billion by 2026, at a CAGR of 10.1%. This growth is driven by the increasing demand for precise motion control applications across several industries, including manufacturing, packaging, and aerospace.

Key features of AC servo drives include high torque-to-weight ratios, precise control of angular position, and fast response times. They are highly effective in applications such as CNC machinery, conveyor systems, and robotics, where accuracy and movement agility are paramount. According to a study by Technavio, the advanced feedback mechanisms implemented in these drives can reduce motion errors by up to 40% compared to traditional systems, significantly enhancing productivity in automated processes. As industries strive for greater efficiency and flexibility, the integration of advanced AC servo drives is set to revolutionize operational capabilities and performance metrics.

Understanding Different Types of AC Servo Drives

When exploring the different types of AC servo drives, understanding their applications and characteristics is crucial for optimizing performance in industrial automation. AC servo drives are designed to maintain precise control over motor functions, offering better efficiency and responsiveness compared to their DC counterparts. They utilize feedback systems to regulate speed, position, and torque, making them ideal for complex automation tasks.

**Tip 1:** When selecting an AC servo drive, consider both the type of application and the required specifications, such as speed and accuracy. High-performance applications, like CNC machinery or robotic arms, will benefit from servos specifically designed for speed and responsiveness.

**Tip 2:** Another key aspect is voltage compatibility. Ensure that the drive you choose aligns with the operational voltage of your system, whether low, medium, or high voltage, to prevent inefficiencies or damage.

In summary, by understanding the distinctions and functionalities of various AC servo drive options, one can enhance automation processes, improve reliability, and boost overall performance.

Top Strategies for Maximizing Performance with Best AC Servo Drives

| Type of AC Servo Drive | Max Torque (Nm) | Max Speed (RPM) | Control Method | Typical Applications |

|---|---|---|---|---|

| Synchronous AC Servo Drive | 5.0 | 3000 | Vector Control | Robotics, CNC Machines |

| Stepper Servo Drive | 2.5 | 1500 | Open Loop Control | 3D Printers, Feeders |

| Brushless DC Servo Drive | 10.0 | 5000 | Closed Loop Control | Automated Guided Vehicles, Conveyors |

| Linear AC Servo Drive | 15.0 | 2000 | PID Control | Packing Machines, Material Handling Systems |

| AC Servo Drive with EtherCAT | 7.5 | 4000 | Ethernet-Based Control | Multi-Axis Robotics, High-speed Machinery |

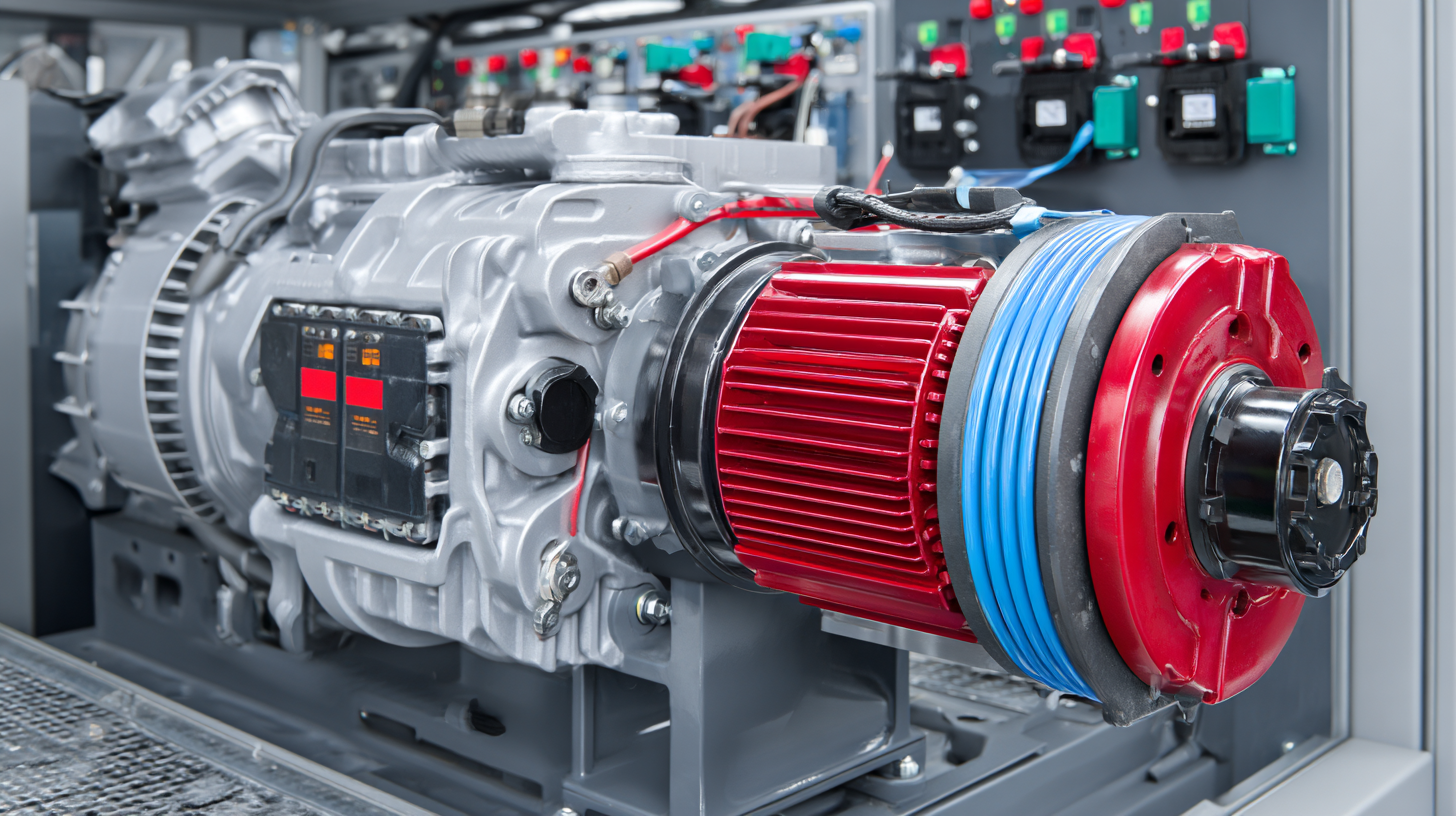

Comparative Analysis of AC Servo Drive Technologies

When considering AC servo drives, understanding the nuances between various technologies can significantly influence performance outcomes.

At the forefront of these technologies are brushless AC motors, which offer higher efficiency and reliability compared to their brushed counterparts.

The absence of brushes eliminates mechanical wear, resulting in longer lifespans and reduced maintenance costs.

This technology excels in applications requiring precision and speed, making it a preferred choice for industries such as robotics and automation.

Another vital technology within the realm of AC servo drives is the use of feedback systems, such as encoders and resolvers.

These devices provide critical real-time data on position, speed, and torque, enabling precise control over the servo motor's performance.

Closed-loop systems leverage this feedback, ensuring accurate positioning and improved response times.

The integration of advanced algorithms further enhances these drives, allowing for adaptive control strategies that optimize performance under varying load conditions.

Understanding the comparative advantages of these technologies is crucial for selecting the right AC servo drive to meet specific operational demands.

Best Practices for Selecting the Right AC Servo Drive

When selecting the right AC servo drive for your applications, understanding the requirements of your specific tasks is crucial. AC servo drives are essential components in the operation of advanced robotics and automation systems, which are increasingly leveraging human-like movement capabilities. Prioritize features such as precision control, response time, and load capacity. These factors can significantly affect the efficiency and accuracy of the robotic applications, especially in scenarios that require intricate movements like flips or fine finger manipulations.

Additionally, consider the integration compatibility of the servo drive with existing systems. The ability to seamlessly connect with your hardware and software can enhance performance and simplify the workflow. Look for drives that offer robust feedback mechanisms and flexibility in programming to adapt to various applications. As industries rush to adopt humanoid robotics, selecting an optimal AC servo drive becomes a strategic advantage in maximizing performance and ensuring the success of your automation projects.

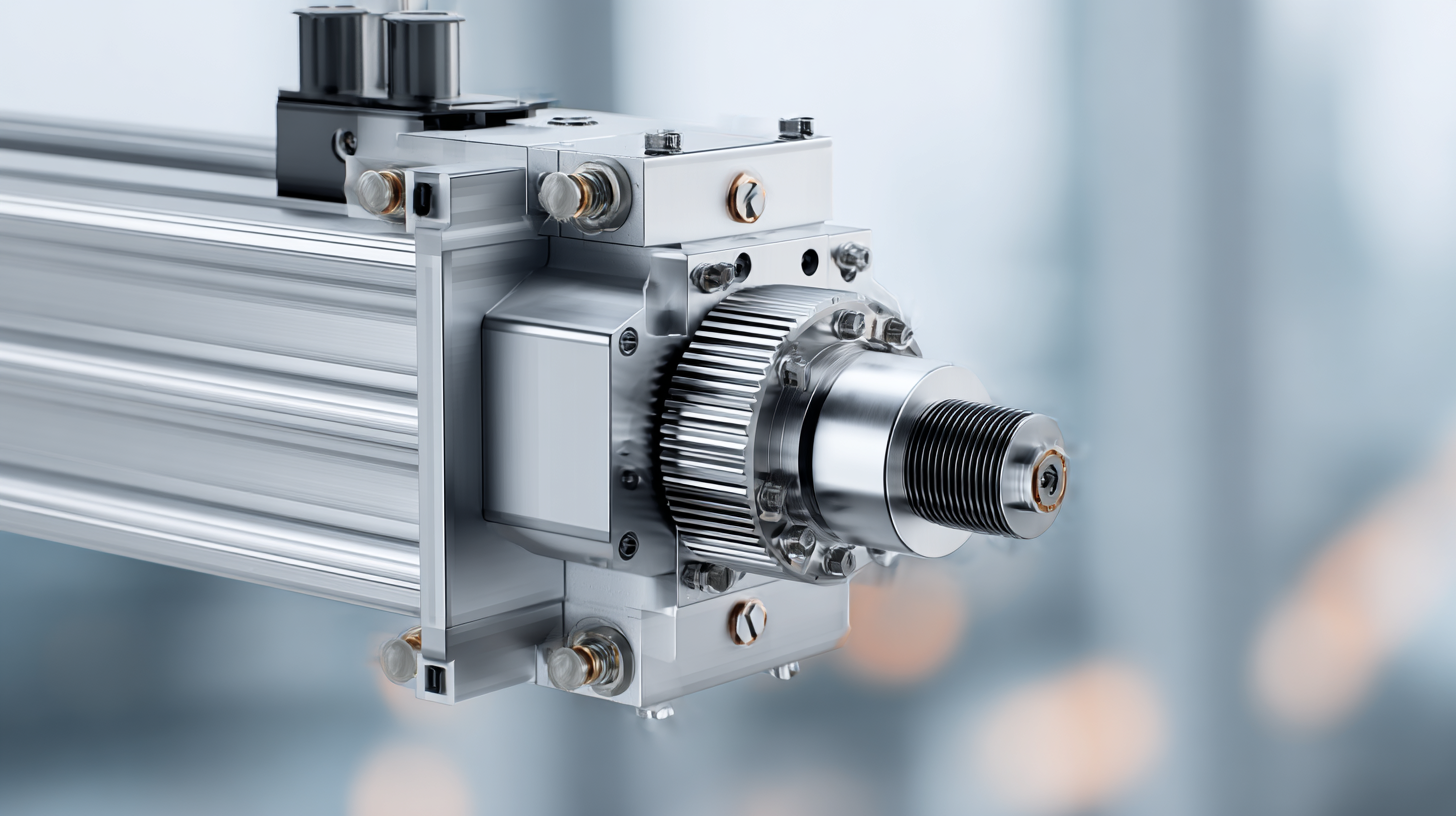

Optimizing Performance: Tips for Using AC Servo Drives Efficiently

When it comes to optimizing the performance of AC servo drives, efficient usage is key. One major aspect to consider is understanding the application requirements. By carefully analyzing the desired torque and speed values for specific tasks, engineers can select the appropriate servo drive that aligns with the operational demands. Advanced servo motor technologies allow for precise control over angular or linear positioning, which is especially crucial in applications like CNC machining where high precision and efficiency are paramount.

Furthermore, leveraging the latest innovations, such as gallium nitride (GaN) technology, can significantly enhance the performance of AC servo drives. GaN-based inverters provide superior efficiency levels, making them ideal for applications that require not just high performance but also energy conservation. As the market for variable frequency drives continues to expand, understanding how to integrate these drives into broader automation systems will be essential for maximizing productivity and minimizing operational costs.