Future Innovations in Servo Motor Drivers Shaping Global Industry Trends in 2025

The landscape of industrial automation is undergoing a revolutionary transformation, with servo motor drivers poised to play a pivotal role in this evolution. As industries globally gravitate towards automation and precision engineering, the market for servo motor drivers is expected to reach USD 6.46 billion by 2025, propelled by advancements in robotics, manufacturing, and aerospace sectors.

According to a recent industry report by MarketsandMarkets, the increasing demand for high-performance motion control solutions and the rise of smart factories are significant drivers behind this growth. This blog will explore the future innovations in servo motor drivers that are shaping global industry trends, examining how technological advancements will enhance efficiency, accuracy, and adaptability in various applications, ultimately setting the stage for a new era of industrial success.

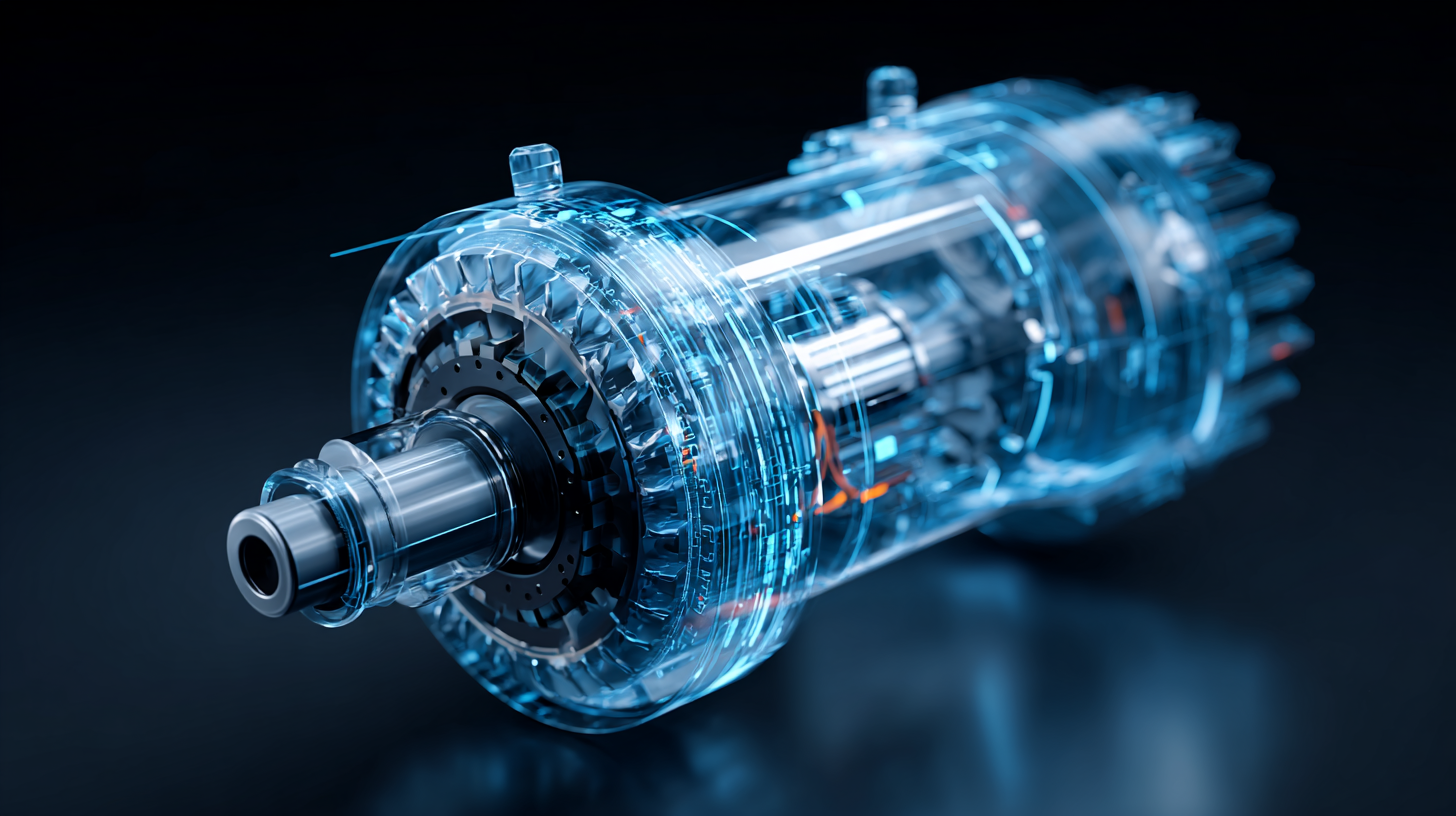

Emerging Technologies in Servo Motor Driver Design for Industry 4.0

The landscape of servo motor driver design is on the brink of a significant evolution, driven by emerging technologies that align with the principles of Industry 4.0. This new industrial revolution emphasizes the integration of intelligent systems, real-time data analytics, and greater automation. As companies strive for more efficient production processes, servo motor drivers are being redesigned to incorporate advanced features. This includes the use of artificial intelligence for predictive maintenance and adaptive performance adjustments, which can enhance productivity and minimize downtime.

Moreover, the incorporation of IoT (Internet of Things) connectivity in servo motor drivers is set to fundamentally transform operational capabilities. With smart devices collecting and sharing data, manufacturers can achieve unprecedented levels of control and oversight. By leveraging cloud technologies, operators can remotely monitor and optimize their systems, ensuring optimal performance and quick response to changing conditions. Additionally, advancements in materials science are facilitating the development of compact and more energy-efficient servo drivers, further supporting the push for sustainable manufacturing practices. As we approach 2025, these innovations will not only redefine efficiency but also pave the way for smarter, more agile manufacturing environments.

Key Trends Driving the Evolution of Servo Motor Drivers by 2025

The future innovations in servo motor drivers are poised to significantly shape global industry trends by 2025. With the servo motors and drives market projected to grow from $14.41 billion to $21.44 billion, experiencing a robust CAGR of 5.8% during 2024-2031, the evolution of these technologies is becoming imperative for various sectors, especially automotive and robotics. The increasing demand for precision and efficiency in automation processes is driving advancements in servo motor technology, from enhanced motion control systems to smarter integration within the mechatronics ecosystem.

Key trends that are expected to drive the evolution of servo motor drivers include the rise of digital servo motors, which offer improved performance and adaptability, and the miniaturization of components, enabling more compact and efficient designs. Furthermore, increased focus on sustainability and energy efficiency is steering innovation in high-voltage and low-voltage applications.

**Tips:** When selecting a servo motor driver, consider the specific application requirements such as torque, speed, and energy efficiency. Always review the latest market reports to stay informed on emerging technologies and industry standards, as these will help in making informed decisions. Engaging with experts in the field can also provide valuable insights into the best technologies suited for your projects.

Impact of AI and Machine Learning on Servo Motor Driver Functionality

The integration of Artificial Intelligence (AI) and Machine Learning (ML) into servo motor drivers is poised to revolutionize the way industries operate in 2025. As these technologies advance, servo motor drivers will become smarter, enabling predictive maintenance and self-optimization, thereby reducing downtime and enhancing operational efficiency. By analyzing real-time data, AI-driven servo motors can adapt their performance to varying loads and conditions, ensuring optimal functionality across diverse applications.

Tip: To leverage the full potential of AI and ML in servo motor systems, consider implementing robust data collection frameworks. This will allow real-time monitoring and provide valuable insights that can inform decision-making processes.

Moreover, AI and ML can enhance the accuracy of servo motor drivers by enabling sophisticated algorithms that improve precision in motion control. This capability is crucial in sectors such as robotics and manufacturing, where even minute inaccuracies can lead to significant operational inefficiencies. By embedding learning algorithms, servo drivers can evolve, learning from past operations to anticipate future needs.

Tip: Investing in training for your engineering team on AI and ML tools can greatly enhance your servo motor applications, ensuring that your systems remain competitive in a rapidly evolving industry landscape.

Sustainability Considerations in Servo Motor Driver Innovations

Sustainability is becoming an essential consideration in the design and development of servo motor drivers, especially as industries move towards more eco-friendly practices. Recent reports highlight that energy-efficient motion solutions can significantly reduce operational costs and lower carbon footprints. For instance, advancements in servo motor technology have led to a reduction of energy consumption by up to 30%, contributing to wider sustainability goals within manufacturing processes. Innovators are focusing on creating seamless environments for original equipment manufacturers (OEMs) to implement these sustainable technologies effectively.

Moreover, the integration of smart manufacturing processes is paving the way for a seamless synergy between robotics and sustainability. The introduction of intelligent systems, like IoT-powered robots designed for waste separation and management, showcases how robotics can aid in developing sustainable solutions. These systems not only optimize operational efficiency but also promote environmental responsibility. With emerging trends in motion control and high-speed automation, industries are poised to embrace new standards that prioritize sustainability while maintaining precision and speed in production. This evolution in servo motor drivers represents a pivotal shift that will define the landscape of global industry by 2025 and beyond.

Future Applications of Servo Motor Drivers Across Diverse Industries

The advancements in servo motor drivers are expected to accelerate their application across various industries, transforming operations in manufacturing, robotics, and automotive sectors by 2025. With the rise of automation and smart technology, servo motor drivers are becoming crucial for ensuring precision and efficiency. For instance, in manufacturing, these drivers are used to enhance the performance of robotic arms, allowing for more intricate tasks with improved speed and accuracy.

**Tip:** When selecting servo motor drivers for your application, consider their compatibility with control systems and feedback mechanisms to optimize performance and reduce downtime.

In the automotive industry, the integration of servo motor drivers is pivotal for electric and hybrid vehicles, where they manage precise movements in steering and braking systems. This enables a smoother driving experience while enhancing safety features. Moreover, the growing trend toward renewable energy sources has spurred innovations in servo applications, particularly in wind and solar energy systems, where they help in adjusting the angles of panels and turbines for maximized efficiency.

**Tip:** Keep an eye on the latest developments in servo technology to identify opportunities for upgrading existing systems, which can lead to substantial energy savings and operational efficiency.