Understanding the Fundamentals of AC Servo Technology: What You Need to Know

The rapid advancements in automation and precision control have made AC servo technology a cornerstone in various industries, including manufacturing, robotics, and aerospace. According to a report by MarketsandMarkets, the global AC servo motor market is expected to reach $11.5 billion by 2025, growing at a CAGR of 6.5%. This significant growth highlights the increasing reliance on AC servo systems for enhancing operational efficiency and precision in machinery. Understanding the fundamentals of AC servo technology is critical for engineers and decision-makers seeking to leverage its capabilities. From its operational mechanics to application areas, this blog will explore essential aspects of AC servo systems, equipping you with the knowledge needed to integrate this technology effectively into your projects.

Key Components of AC Servo Systems Explained

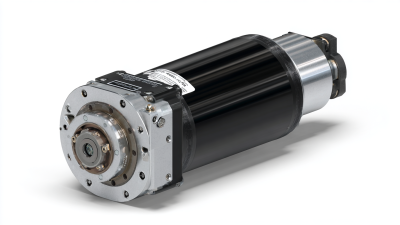

AC servo systems are intricate setups that rely on several key components to function effectively. At the heart of an AC servo system is the servo motor, which converts electrical energy into mechanical energy, providing precise control of motion. These motors are typically brushless, offering high efficiency, durability, and excellent performance in a variety of industrial applications. Coupled with an encoder, which provides real-time feedback about the motor’s position and speed, the servo motor can achieve highly accurate and responsive control.

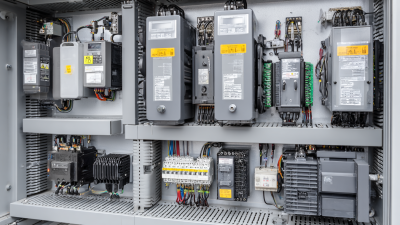

Another critical element is the servo drive, responsible for powering the motor and interpreting feedback signals from the encoder. The drive adjusts the current and voltage supplied to the motor to maintain precise control over its motion, allowing for smooth acceleration and deceleration. Additionally, a control system, often implemented with PLCs or microcontrollers, coordinates these components, ensuring that they work harmoniously. Together, these parts create an AC servo system capable of executing complex movements with remarkable precision, making it a popular choice in automation, robotics, and manufacturing sectors.

Understanding the Fundamentals of AC Servo Technology

Key Components of AC Servo Systems Explained

This chart represents the impact level of key components in AC servo systems. Each component plays a crucial role, with the motor being the most impactful followed by the controller, feedback device, and power supply.

How AC Servo Technology Works: A Step-by-Step Guide

AC servo technology is a pivotal innovation in automation and control systems, characterized by its precision and efficiency. To grasp how this technology works, it’s important to break down the components and their functions. At the heart of an AC servo system are the servo motor and the feedback device, typically an encoder. The servo motor is designed to provide high torque and accurate position control, responding to signals from a controller that dictate its desired behavior. The encoder continuously monitors the motor's position and speed, sending real-time data back to the controller to ensure that any deviations from the set parameters are quickly corrected.

The interaction between these components forms a closed-loop system, which enhances responsiveness and accuracy. When the controller sends a command, the servo motor begins to rotate. As it moves, the encoder tracks its position and relays this information back, allowing the controller to adjust the motor's operation to achieve the desired trajectory. This constant feedback and adjustment process is what sets AC servo technology apart from other systems, enabling it to maintain high performance even in dynamic environments. Understanding these fundamental elements is essential for anyone looking to leverage AC servo technology in their applications.

Selecting the Right AC Servo Motor for Your Application

Selecting the right AC servo motor for your application is a critical step that can significantly influence the performance and efficiency of your system. The first consideration should be the specific requirements of your application, such as speed, torque, and precision. Each application may have different demands; for instance, robotics often require high torque and precise control, while CNC machining may prioritize speed and smooth motion. Understanding these needs helps in narrowing down the options available, ensuring the selected unit matches the performance characteristics required.

Selecting the right AC servo motor for your application is a critical step that can significantly influence the performance and efficiency of your system. The first consideration should be the specific requirements of your application, such as speed, torque, and precision. Each application may have different demands; for instance, robotics often require high torque and precise control, while CNC machining may prioritize speed and smooth motion. Understanding these needs helps in narrowing down the options available, ensuring the selected unit matches the performance characteristics required.

Another essential factor to consider is the motor's compatibility with your control system. AC servo motors come with various feedback mechanisms, such as encoders and resolvers, which affect how well they integrate with existing systems. Evaluating your control architecture and the communication protocols it supports can help in selecting a motor that not only meets your application needs but also fits seamlessly into your setup. Additionally, assessing the environment in which the motor will operate, including factors like temperature and humidity, is vital for ensuring longevity and reliability. Thus, careful consideration of all these aspects will lead to a more effective selection process.

Common Applications of AC Servo Technology in Industry

AC servo technology has become an integral component in various industrial applications, largely due to its precision and efficiency. Industries are increasingly adopting AC servo systems for their ability to enhance automation processes, notably in robotics, where precision and response time are critical. According to a report from an industry analysis data center, the global market for servo motors and drives was valued at $14.5075 billion in 2023, with projections indicating growth to $18.8776 billion by 2028. This represents a substantial annual growth rate, highlighting the technology's expanding role in modern manufacturing environments.

In the industrial robotics sector, AC servo systems are primarily used in applications such as robotic arms, automated guided vehicles (AGVs), and assembly line operations. These systems improve the functionality of robots, allowing for rapid and accurate positioning, which is essential for tasks such as welding, packaging, and material handling. Furthermore, the recent Taiwan Robotics and Smart Automation Expo underscored the industry's shift towards smarter automation solutions, with major manufacturers showcasing innovations that employ advanced servo technology to meet evolving market demands. This indicates a clear trajectory towards increased adoption of AC servo technology in various sectors, driving competitive advantages through improved efficiency and reduced operational costs.

Understanding the Fundamentals of AC Servo Technology: What You Need to Know - Common Applications of AC Servo Technology in Industry

| Application Area | Description | Key Benefits |

|---|---|---|

| Robotics | Used in robotic arms for precision movements and tasks. | High accuracy, repeatability, and speed. |

| Material Handling | Automates the movement and sorting of materials. | Increased efficiency and reduced labor costs. |

| CNC Machinery | Controls the precision cutting and shaping of materials. | Enhanced precision and surface finish quality. |

| Packaging | Automates the packing process for various goods. | Faster packaging speeds and reduced waste. |

| Textile Production | Drives weaving and sewing machines for fabric production. | Improves fabric quality and production rates. |

Troubleshooting Tips for AC Servo Systems: What to Look For

When dealing with AC servo systems, troubleshooting is a critical skill that can significantly reduce downtime and enhance performance. Common issues include inaccurate positioning, excessive vibration, and overheating. According to a report by the Industrial Automation Association, nearly 30% of machine malfunctions stem from controller errors, underscoring the importance of regular firmware updates and calibration checks.

Tip: Always monitor the servo driver parameters to ensure they're within manufacturer specifications. This includes checking feedback signals, coordinate system configurations, and the motor's temperature. Anomalies in these areas often indicate underlying issues that need immediate attention.

Another common pitfall is neglecting environmental factors such as humidity and dust, which can severely impact sensor performance. The National Electrical Manufacturers Association found that over 25% of operational delays in automated systems result from environmental contamination.

Tip: Implement regular cleanings and consider protective enclosures for sensitive components. This proactive approach not only extends the lifespan of your system but also maximizes its reliability and efficiency in the long run.

Related Posts

-

Top Strategies for Maximizing Performance with Best AC Servo Drives

-

Future Innovations in Servo Motor Drivers Shaping Global Industry Trends in 2025

-

5 Best Ways to Optimize Motor Power for Industrial Efficiency

-

Exploring 2025 Tech Trends: How to Choose the Best Frameless Motor for Your Business Needs

-

Innovative Solutions for Achieving Maximum Efficiency with Best DC Servo Motors

-

Overcoming Common Challenges with Servo Motors: A Deep Dive into Performance and Reliability Issues