7 Essential Tips for Choosing the Best High Torque Servo Based on Performance Data

Choosing the right high torque servo for your project can make a significant difference in performance and efficiency. With numerous options available on the market, it often feels overwhelming to pinpoint which one best suits your specific needs. The critical factor lies in understanding performance data, as it provides insights into a servo's capabilities, responsiveness, and overall reliability under varying conditions.

In this guide, we will explore seven essential tips to help you navigate the selection process effectively, ensuring that you choose a high torque servo that not only meets but exceeds your expectations. By leveraging key performance metrics and characteristics, you will be equipped to make an informed decision that enhances your project's success.

Understanding High Torque Servo Motors: Key Performance Metrics

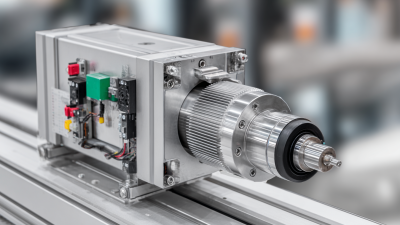

When selecting a high torque servo motor, understanding key performance metrics is crucial for ensuring optimal functionality in your application. These metrics include torque, speed, and precision. For instance, recent studies have highlighted that servo motors provide superior control quality, making them essential for high-precision environments like CNC machining. The demand for these motors has increased as industries seek to enhance their manufacturing capabilities. Effective servo motors can significantly improve not only speed but also efficiency, thus contributing to better overall system performance.

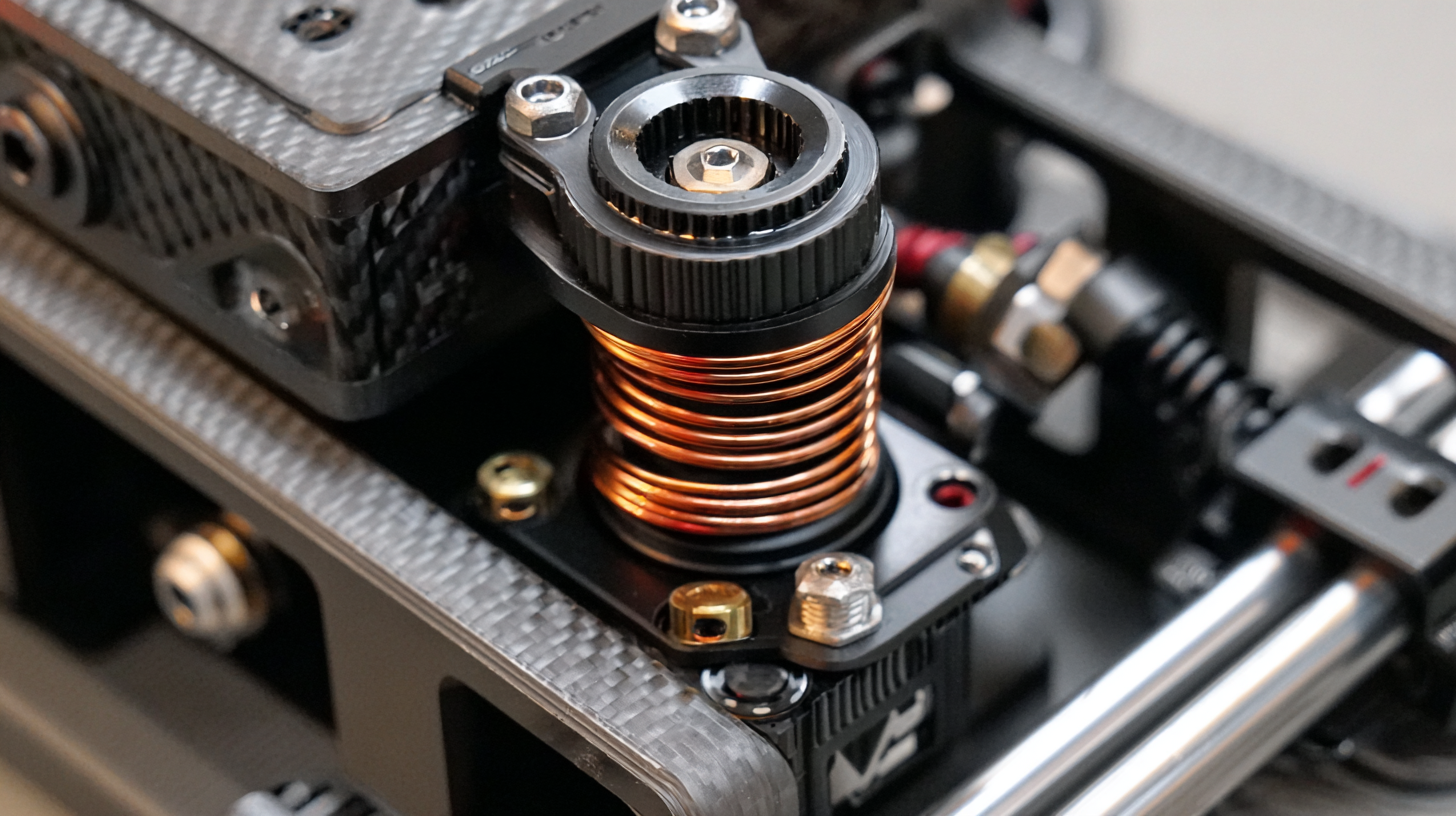

Tip 1: Evaluate the torque-to-weight ratio. A higher ratio indicates better performance in terms of load handling capabilities, enabling the servo to operate efficiently under various conditions.

Tip 2: Consider the integration of drive systems. Modern servo drives offer remarkable performance improvements, but it is essential to analyze factors such as cabling and form factor that can impact installation and operation.

Additionally, using data analysis for predictive maintenance can help in monitoring performance metrics like vibration and temperature, which are critical for maintaining the longevity and reliability of servo motors. With these considerations, choosing the right servo motor based on performance data becomes a strategic advantage for enhancing automation in industrial settings.

Evaluating Speed and Responsiveness in Servo Motor Selection

When selecting a high torque servo, evaluating speed and responsiveness is crucial. High torque servos are primarily used in applications that require quick and precise movements, such as robotics and automation. The performance data, particularly the speed ratings in RPM (revolutions per minute) and the response time, provides insight into how well the servo can adapt to varying loads and commands. A servo that exhibits swift acceleration and deceleration while maintaining accuracy in position can significantly enhance the overall efficiency of your system, leading to better performance and reliability.

Another key aspect to consider is the servo's control resolution and feedback mechanism. A responsive servo motor not only moves quickly but also provides real-time feedback, allowing for adjustments to be made on the fly. This is especially important in complex applications where timing and precision are vital. When comparing different models, look for specifications that detail the servo's latency, update frequency, and how it performs under different operational conditions. This comprehensive evaluation of speed and responsiveness will ultimately guide you in choosing the best servo that meets your performance needs.

Analyzing Load Capacity and Torque Ratings for Optimal Performance

When selecting a high torque servo, understanding load capacity and torque ratings is crucial for optimal performance. Load capacity refers to the maximum weight or force that the servo can manipulate effectively. To ensure reliable operation, it is essential to match the servo's load capacity with the demands of your application. An overworked servo can lead to premature failure, reduced efficiency, and subpar performance. Therefore, carefully assess the load your project will require and choose a servo that comfortably exceeds that threshold.

Furthermore, torque ratings offer insight into the servo's ability to perform tasks under varying conditions. Torque, measured in ounce-inches or Newton-meters, indicates the rotational force the servo can exert. A higher torque rating usually translates to better performance in applications involving heavy loads or fast movements. It is vital to analyze not just the peak torque, but also the continuous torque capability, as this reflects the servo's ability to handle sustained loads during operation. By thoroughly evaluating these metrics, you can ensure that your chosen high torque servo meets the specific needs of your project while maximizing efficiency and longevity.

Comparing Control Methods: Analog vs. Digital Servo Systems

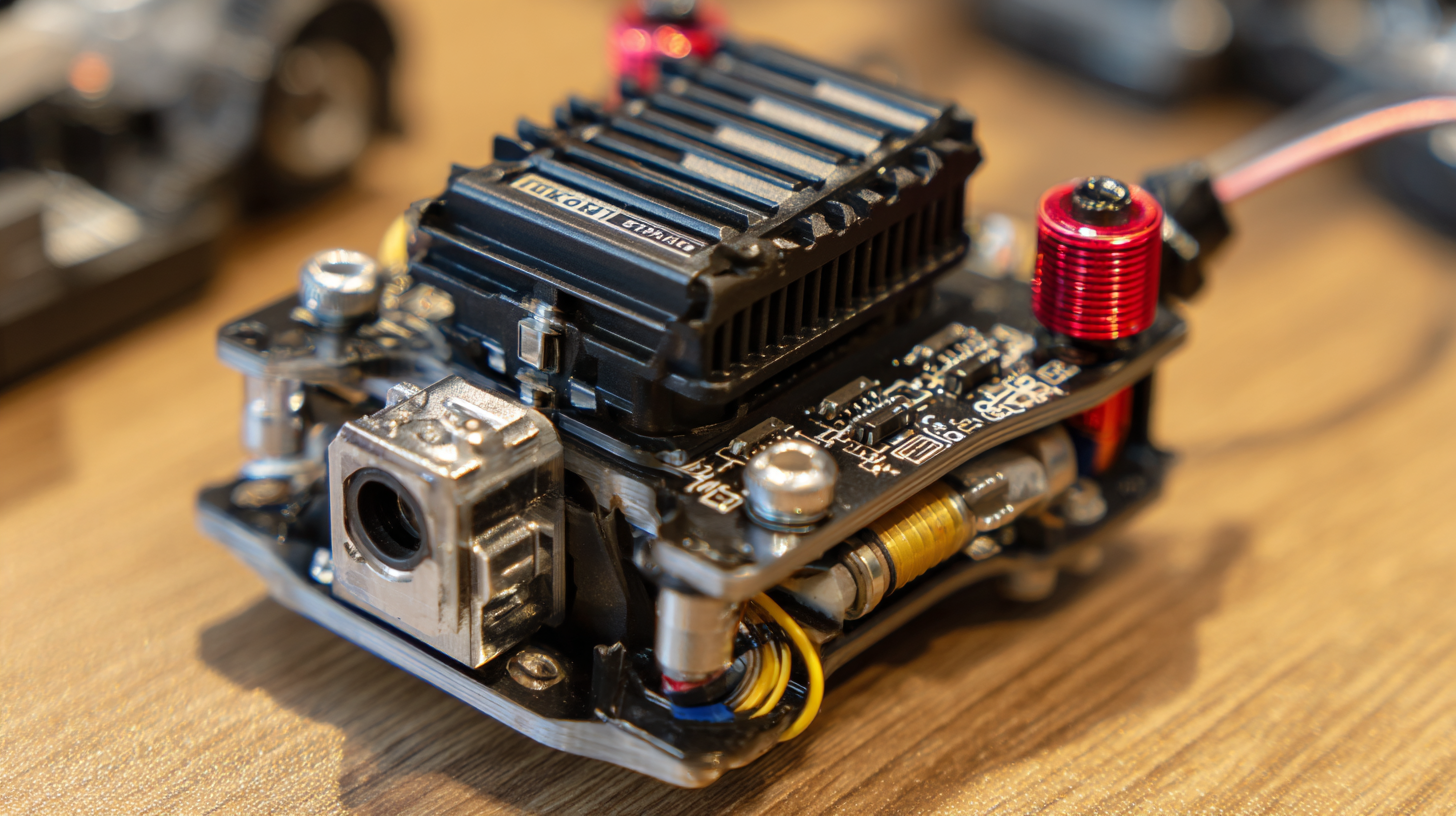

When it comes to selecting the best high torque servo, understanding the differences between analog and digital servo systems is crucial. Analog servos are often simpler and cost-effective, making them an attractive option for basic applications. However, they typically exhibit less precision and responsiveness compared to their digital counterparts. Digital servos, on the other hand, employ advanced control algorithms that provide improved performance, better torque control, and increased speed. This makes them ideal for demanding applications where high precision is essential.

One essential tip for choosing a servo based on performance data is to assess the specific requirements of your application. Consider factors such as the load to be moved, the required speed, and the level of precision needed. This analysis will guide you in deciding whether an analog or digital system is more suitable for your needs. Additionally, pay attention to the feedback mechanisms integrated into the servo systems. Digital servos often feature more advanced feedback systems that enhance their overall performance, making them a superior choice for high-stakes environments.

Another key consideration is the power supply requirements and compatibility with your existing systems. Ensure that the servo you choose can operate effectively within your setup while providing enough torque for your application. This consideration can ultimately save you time and resources, ensuring that your project runs smoothly and efficiently.

7 Essential Tips for Choosing the Best High Torque Servo Based on Performance Data

| Servo Type | Torque (kg-cm) | Speed (sec/60°) | Control Method | Feedback Type | Operating Voltage (V) |

|---|---|---|---|---|---|

| Analog Servo | 20 | 0.20 | Analog | No Feedback | 5 - 6 |

| Digital Servo | 25 | 0.15 | Digital | Position Feedback | 6 - 7.4 |

| High Torque Analog Servo | 30 | 0.25 | Analog | No Feedback | 6 - 7.4 |

| High Torque Digital Servo | 35 | 0.12 | Digital | Position Feedback | 7.4 - 8.4 |

Assessing Durability and Reliability for Long-Term Usage in Applications

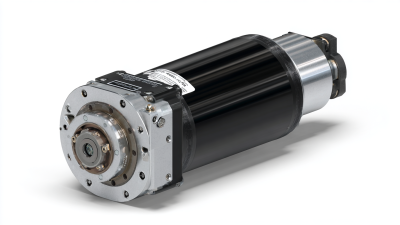

When selecting a high torque servo, assessing its durability and reliability is crucial for ensuring long-term performance in various applications. A reliable servo not only minimizes downtime but also enhances overall system efficiency. Look for servos that are constructed with high-quality materials and designed to withstand harsh operating conditions. Products with robust housings and protective features against dust, moisture, and temperature fluctuations will serve better in demanding environments.

Additionally, it's important to evaluate the servo's performance data over extended periods. Analyze factors such as failure rates, maintenance requirements, and operational lifecycle. Manufacturers that provide comprehensive testing results, including stress tests and longevity assessments, can offer valuable insights. A servo that performs consistently under stress is an indicator of its reliability. By prioritizing these aspects in your selection process, you can ensure that your high torque servo will not only meet immediate demands but will also stand the test of time, thereby optimizing performance across its lifespan.

Related Posts

-

Addressing Common Calamities in High Torque Motor Procurement: A Global Perspective

-

7 Essential Tips for Maximizing Performance with AC Servo Motors

-

7 Reasons Why Your Factory Needs an AC Servo Motor Today

-

Innovative Solutions for Achieving Maximum Efficiency with Best DC Servo Motors

-

Advanced Solutions for Enhancing Efficiency with Hollow Shaft Servo Motors

-

Future Innovations in Servo Motor Drivers Shaping Global Industry Trends in 2025