Advanced Solutions for Enhancing Efficiency with Hollow Shaft Servo Motors

In today's rapidly evolving industrial landscape, the demand for precision and efficiency has driven significant advancements in motor technology, particularly with hollow shaft servo motors. According to a recent report from the Global Industry Analysts, the servo motor market is projected to reach $9 billion by 2027, with a notable portion attributed to the growing preference for hollow shaft designs in automation applications. These motors stand out for their unique ability to reduce complexity within mechanical setups, allowing for more efficient power transmission and integration in a variety of systems. As industries increasingly adopt smart manufacturing practices, the advantages of hollow shaft servo motors—such as enhanced torque density, reduced size, and improved response times—make them a compelling alternative worth exploring.

This blog will delve into advanced solutions that highlight the efficiency enhancements offered by hollow shaft servo motors, illuminating the transformative impact they can have on modern operations.

Understanding the Mechanisms of Hollow Shaft Servo Motors

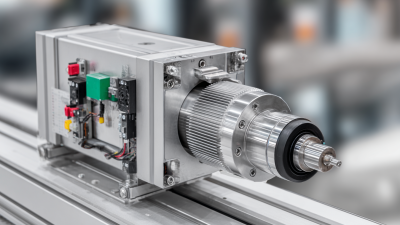

Hollow shaft servo motors have emerged as a pivotal technology for enhancing operational efficiency in various industrial applications. Their unique design allows for a hollow center, enabling the passage of shafts, cables, or other components without the need for additional couplings. This feature not only saves valuable space but also simplifies assembly and integration into complex systems. By minimizing mechanical linkage and potential misalignments, hollow shaft servo motors significantly improve the overall reliability of machinery, ultimately leading to enhanced productivity.

Understanding the mechanisms behind hollow shaft servo motors reveals why they are becoming increasingly popular in automation and robotics. Equipped with advanced feedback systems, these motors offer precise control over speed, position, and torque. The integration of high-resolution encoders enables real-time performance monitoring, contributing to adaptive adjustments that optimize workflow. As industries strive for greater efficiency, the ability of hollow shaft servo motors to deliver consistent, high-precision results is not only beneficial but essential for maintaining competitive advantages in the market.

Benefits of Using Hollow Shaft Technology in Automation

Hollow shaft technology is revolutionizing automation by providing unmatched efficiency and flexibility in system design. By eliminating the need for traditional shafts, hollow shaft servo motors allow for easier integration into tight spaces and reduce the overall footprint of machinery. This innovation not only streamlines the design process but also enhances performance by minimizing the number of components, thereby reducing potential points of failure.

Incorporating hollow shaft technology can lead to significant operational benefits. For instance, the design allows for direct integration of sensors and other necessary components within the motor itself, simplifying the assembly process. Additionally, this technology often results in lighter setups, which can improve the responsiveness of automated systems. With advancements similar to those seen in driveline innovations, manufacturing and automation industries are increasingly leaning towards solutions that boost efficiency while maintaining high standards of reliability. This paradigm shift underscores the importance of adopting cutting-edge technologies in a rapidly evolving marketplace.

Key Strategies for Optimizing Performance in Servo Systems

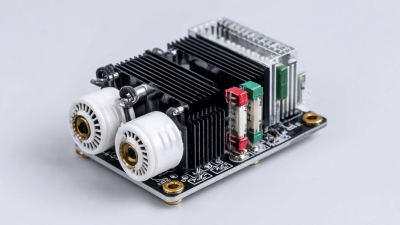

Hollow shaft servo motors are increasingly being utilized in various applications due to their compact design and efficiency. Optimizing performance in servo systems is essential for ensuring precise control and reliability. One key strategy in achieving this is through proper alignment of the motor and load. Misalignment can lead to increased wear and tear, causing inefficiencies and downtime.

**Tip 1:** Always use alignment tools to ensure that the motor and load are perfectly aligned. This will not only enhance the lifespan of the components but also improve overall system efficiency.

Another important aspect is the tuning of the servo parameters. Properly setting the proportional, integral, and derivative gains can greatly improve responsiveness and stability in motion control applications. This can be accomplished through trial and error or using simulation tools for better accuracy.

**Tip 2:** Regularly review and adjust the gain settings based on performance feedback. Fine-tuning these parameters can lead to significant improvements in efficacy, making your servo system perform at its best.

Lastly, incorporating feedback mechanisms such as encoders can vastly enhance the precision of the system. Feedback loops allow for real-time adjustments and correction, which is essential for high-speed operations.

**Tip 3:** Invest in high-resolution encoders to ensure accurate position and velocity readings. This will help in minimizing errors and enhancing the overall efficiency of the servo system.

Advanced Solutions for Enhancing Efficiency with Hollow Shaft Servo Motors - Key Strategies for Optimizing Performance in Servo Systems

| Parameter | Value | Unit |

|---|---|---|

| Torque Rating | 150 | Nm |

| Max Speed | 3000 | RPM |

| Feedback Type | Absolute Encoder | |

| Communication Protocol | EtherCAT | |

| Efficiency | 95 | % |

| Weight | 10 | kg |

| Operating Voltage | 220 | V |

| Protection Class | IP65 |

Integrating Hollow Shaft Servo Motors with IoT Solutions

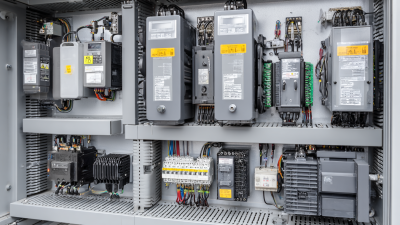

The integration of hollow shaft servo motors with IoT solutions is transforming the landscape of industrial automation. According to a recent report by MarketsandMarkets, the global IoT in manufacturing market is projected to reach $405.3 billion by 2025, growing at a CAGR of 25.1%. This growth is driven, in part, by advancements in motor technology, particularly hollow shaft designs, which provide significant advantages in terms of space-saving and flexibility in design.

Hollow shaft servo motors eliminate the need for additional couplings, making them ideal for applications where space is a premium.

Additionally, the synergy created by IoT and hollow shaft servo motors enhances operational efficiency through real-time data collection and analysis. With embedded sensors, these motors can transmit performance data back to central control systems, allowing for predictive maintenance and minimizing downtime. A study by McKinsey highlights that companies leveraging IoT technologies can realize up to a 30% improvement in operational efficiency. Moreover, by integrating hollow shaft servo motors into IoT frameworks, businesses can achieve greater precision in their manufacturing processes, leading to improved product quality and reduced waste. The combination of these technologies is setting new standards for performance and reliability in the industry.

Future Trends: Innovations in Hollow Shaft Motor Applications

The landscape of engineering technology is rapidly evolving, particularly with the growing reliance on hollow shaft servo motors. These motors are not only efficient in terms of space but also enhance overall system performance. Future trends indicate that innovations such as increased integration with IoT devices and advancements in materials science will further propel the applications of hollow shaft motors in various industries, from robotics to automotive engineering.

As industries look to leverage the unique capabilities of hollow shaft motors, here are some tips for maximizing their potential. First, consider the design requirements of your application; hollow shaft motors can save space and reduce weight, so optimizing for these aspects can significantly enhance performance. Additionally, investing in advanced control systems can provide better responsiveness and efficiency, which is crucial for high-precision operations.

Another trend to watch is the growing emphasis on sustainability. Manufacturers are exploring eco-friendly materials and energy-efficient designs. Tips for embracing this trend include assessing your supply chain for sustainable options and implementing energy monitoring solutions to track and improve your motor system's efficiency. By staying ahead of these innovations, businesses can not only improve their operational efficiency but also contribute to a more sustainable future in engineering.

Related Posts

-

7 Reasons Why Your Factory Needs an AC Servo Motor Today

-

Overcoming Common Challenges with Servo Motors: A Deep Dive into Performance and Reliability Issues

-

Top Strategies for Maximizing Performance with Best AC Servo Drives

-

Explore the Technical Specifications of the Best Servo Drives and How to Choose the Right One for Your Needs

-

Future Trends in Technology 2025 How to Choose the Best Servo Amplifier for Your Applications

-

Understanding the Advantages of Integrated Servo Motors in Modern Automation