Electric Servo Motor Showdown: Which Type Reigns Supreme in Performance and Efficiency?

In the ever-evolving world of automation and manufacturing, the performance and efficiency of electric servo motors remain pivotal for optimizing production processes. As reported by industry expert firms such as MarketsandMarkets, the electric servo motor market is expected to reach USD 14.41 billion by 2025, driven by the rising demand for automation across various sectors. With advancements in technology, different types of electric servo motors—such as brushed, brushless, and stepper—each present unique benefits and specifications that can significantly impact operational efficiency and performance. This blog delves into a comprehensive comparison of these types, analyzing their characteristics, advantages, and applications to determine which electric servo motor truly reigns supreme in the contemporary industrial landscape.

Types of Electric Servo Motors: An Overview of Key Variations

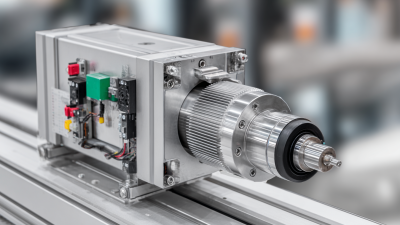

Electric servo motors come in various types, each offering unique advantages tailored to specific applications. Among the most notable are brushed and brushless servo motors, which differ primarily in their construction and operational efficiency. Brushless servo motors, for example, are known for their higher reliability and longer lifespan, thanks to the absence of brushes that wear out. According to industry reports, brushless motors can achieve efficiency rates exceeding 90%, making them ideal for applications requiring high precision and low maintenance.

Another significant category is geared motors, which combine the attributes of servos with gearing systems to enhance torque output. These geared motors are praised for their versatility and are suitable for numerous applications, from robotics to HVAC systems. Recent analysis found that geared servo motors can deliver superior performance in high-torque scenarios, making them a preferred choice for tasks that demand consistent and reliable power. In fact, the versatility of these motors allows them to perform effectively across a range of non-linear loads typically found in household applications, underscoring their importance in modern engineering and automation solutions.

Electric Servo Motor Showdown: Which Type Reigns Supreme in Performance and Efficiency?

| Motor Type | Torque (Nm) | Speed (RPM) | Efficiency (%) | Control Type | Typical Applications |

|---|---|---|---|---|---|

| AC Servo Motor | 5-100 | 1500-3000 | 85-95 | Open Loop / Closed Loop | Robotics, CNC Machines |

| DC Servo Motor | 1-50 | 2000-6000 | 75-90 | Closed Loop | Automated Systems, Conveyors |

| Stepper Motor | 0.5-10 | 100-300 | 70-80 | Open Loop | 3D Printers, CNC Machines |

| Brushless DC Motor | 1-90 | 2000-8000 | 90-98 | Closed Loop | Drones, Electric Vehicles |

Comparing Performance Metrics: Torque, Speed, and Response Times

In the world of electric servo motors, the performance metrics of torque, speed, and response times are pivotal in determining their effectiveness for various applications. Torque, a measure of rotational force, is essential in applications requiring substantial load handling. A motor with higher torque can facilitate more demanding tasks, making it indispensable in robotics and industrial machinery. Conversely, achieving high speed often leads to enhanced productivity and efficiency; therefore, selecting a motor that strikes a balance between torque and speed is crucial for optimal performance.

Response times play an equally vital role when it comes to the effectiveness of servo motors in real-time applications. Fast response times allow for quick adjustments to load changes, ensuring smooth operation in applications where precision is critical. Motors with superior response characteristics are particularly favored in automated systems where rapid feedback loops are essential for maintaining accuracy and performance, such as in CNC machines or drone technology. By evaluating these metrics, users can make informed decisions about which type of electric servo motor best fits their specific performance requirements.

Efficiency Standards: How Different Types Measure Up

When it comes to electric servo motors, efficiency is a critical factor that influences performance across various applications. Different types of servo motors exhibit distinct efficiency standards, making it essential to understand how they stack up against one another. For instance, brushless DC servo motors are renowned for their superior efficiency due to their lack of friction from brushes, which not only reduces wear but also minimizes energy loss. This allows them to maintain high torque and speed control even at lower power inputs, making them ideal for precise applications.

On the other hand, stepper motors, while simpler in design and typically less expensive, can struggle with efficiency in high-speed applications. Their operation involves energizing coils in sequence, leading to potential energy wastage when stopping or starting. Additionally, the holding torque required often leads to overheating, impacting their overall performance. By comparing these and other types, such as AC servo motors, industry professionals can make more informed decisions that prioritize both performance and energy consumption needed for their specific use cases. Each motor type serves a unique niche, driving the ongoing innovation in the field of automation and robotics.

Application Suitability: Where Each Servo Motor Type Excels

In the realm of automation and precision control, servo motors are indispensable, each type catering to unique applications.

For instance, AC servo motors are renowned for their superior speed and efficiency, making them ideal for high-performance tasks such as CNC machinery and robotic arms. Their ability to operate at varying speeds without loss of torque allows them to handle complex motions with remarkable precision, thus excelling in manufacturing environments where accuracy is paramount.

In the realm of automation and precision control, servo motors are indispensable, each type catering to unique applications.

For instance, AC servo motors are renowned for their superior speed and efficiency, making them ideal for high-performance tasks such as CNC machinery and robotic arms. Their ability to operate at varying speeds without loss of torque allows them to handle complex motions with remarkable precision, thus excelling in manufacturing environments where accuracy is paramount.

On the other hand, DC servo motors shine in applications requiring quick response times and ease of control. Found in devices like hobbyist robotics and conveyor systems, they offer a simpler design and a more straightforward interface, making them accessible for projects with less demanding specifications. Additionally, stepper motors, a subset of DC technology, are perfect for applications needing precise positioning without feedback mechanisms, such as 3D printers or scanners, where incremental movement is crucial. Each type of servo motor has its niche, ensuring that regardless of the task, there exists a solution designed to meet the specific demands of efficiency and performance.

Future Trends: Innovations Shaping the Servo Motor Landscape

As industries continue to evolve, electric servo motors are at the forefront of innovation, driving advancements in automation and precision control. One of the most significant trends shaping the servo motor landscape is the integration of smart technology. Manufacturers are now embedding sensors and IoT capabilities into servo motors, allowing for real-time monitoring and data analytics. This evolution not only enhances performance but also contributes to predictive maintenance, reducing downtime and extending the lifespan of machinery.

Another transformative development is the shift towards more energy-efficient designs. With growing environmental concerns and regulations regarding energy consumption, researchers are focusing on creating servo motors that deliver maximum output while minimizing energy usage. Innovations such as advanced materials and refined manufacturing processes are leading to lighter, more powerful motors that boast an impressive efficiency rating. As these trends continue to unfold, the future of electric servo motors promises not only improved performance but also a more sustainable approach to industrial operations.

Related Posts

-

Overcoming Common Challenges with Servo Motors: A Deep Dive into Performance and Reliability Issues

-

Understanding the Advantages of Integrated Servo Motors in Modern Automation

-

Advanced Solutions for Enhancing Efficiency with Hollow Shaft Servo Motors

-

7 Reasons Why Your Factory Needs an AC Servo Motor Today

-

Explore the Technical Specifications of the Best Servo Drives and How to Choose the Right One for Your Needs

-

Exploring 2025 Tech Trends: How to Choose the Best Frameless Motor for Your Business Needs