Unlocking Efficiency: How Industrial Servo Motors Transform Automation in Manufacturing

The integration of industrial servo motors in manufacturing processes is revolutionizing the automation landscape, driving a notable increase in operational efficiency and productivity. According to a report by MarketsandMarkets, the industrial automation market is projected to reach $214 billion by 2026, with a significant portion attributed to advancements in servo technology. Industrial servo systems enable precise control of movement and speed, essential for modern manufacturing demands. With an increasing emphasis on minimizing downtimes and maximizing output, industries are embracing these sophisticated motors to streamline operations. Additionally, research by Allied Market Research highlights that the global servo motor market is expected to grow from $12.8 billion in 2020 to $25.7 billion by 2027, underscoring the growing reliance on industrial servo solutions for enhancing efficiency and competitiveness in manufacturing sectors.

Revolutionizing Manufacturing Processes with Industrial Servo Motors

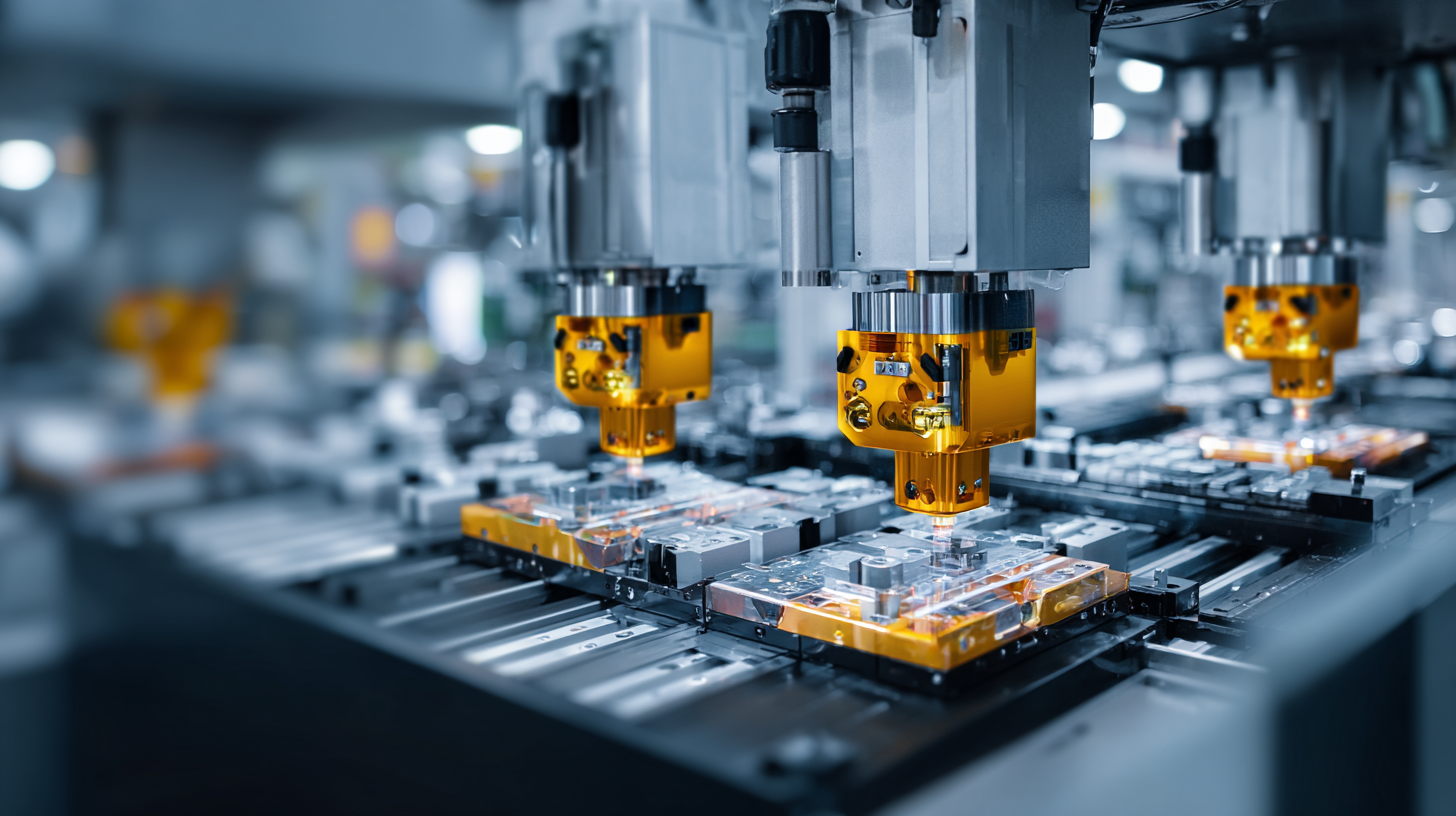

Industrial servo motors are at the forefront of revolutionizing manufacturing processes, providing unparalleled precision and efficiency in automation. By employing advanced control techniques, these motors enable manufacturers to achieve high-speed operations with minimal energy consumption. This level of control not only enhances the accuracy of machining and assembly tasks but also significantly reduces waste, leading to more sustainable production practices.

The integration of industrial servo motors into manufacturing systems allows for greater flexibility in production lines. This adaptability means manufacturers can easily reconfigure their operations to accommodate different products or adjust to varying demand levels without sacrificing output quality or speed. As a result, businesses are increasingly turning to servo technology to maintain competitiveness in an ever-evolving market landscape, ensuring they can meet customer demands while optimizing their resource utilization.

Enhancing Precision and Control in Automation Systems

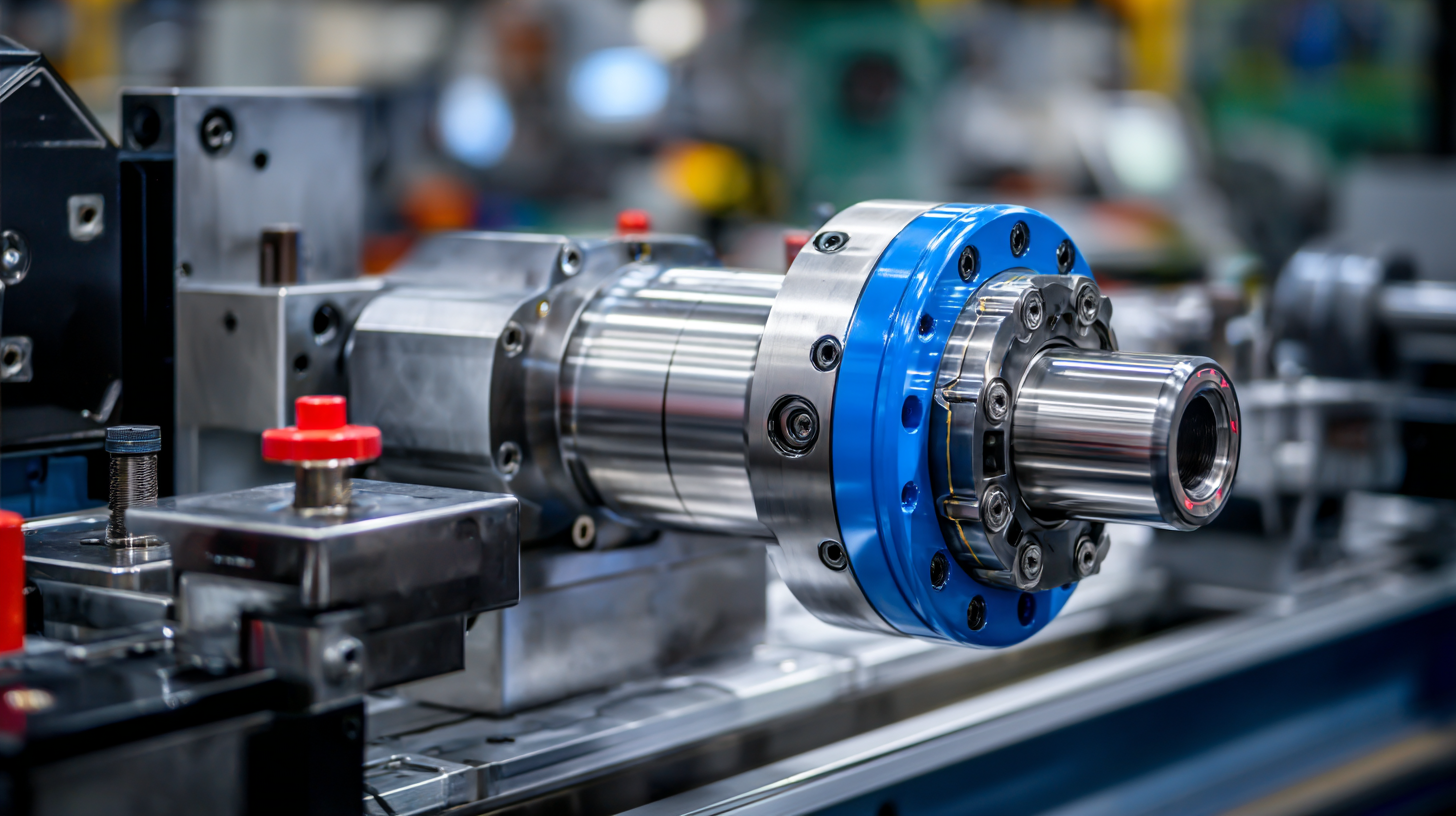

Industrial servo motors play a pivotal role in enhancing precision and control within automation systems in manufacturing. By utilizing closed-loop control mechanisms, these motors can adjust their position, velocity, and torque with remarkable accuracy. This capability allows for the intricate manipulation of machinery, resulting in improved product quality and reduced waste. As manufacturers seek to optimize their production processes, the precision offered by servo motors becomes an invaluable asset, enabling tighter tolerances and more complex operations.

Furthermore, the adaptability of servo motors enables them to be integrated into a variety of automation applications, from robotic arms to conveyor systems. Their ability to respond swiftly to changes in the production environment allows for real-time adjustments, ensuring that operational efficiency is maintained. This level of control minimizes downtime and enhances the overall throughput of manufacturing processes, making servo motors essential for modern industrial automation. As industries continue to evolve, the demand for precise and efficient automation solutions solidifies the importance of industrial servo motors in driving productivity forward.

Cost Savings and Energy Efficiency through Advanced Servo Technologies

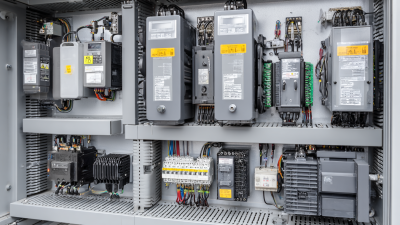

The increasing demand for cost savings and energy efficiency in manufacturing is driving the rapid adoption of advanced servo technologies. The global energy efficient motor market is projected to grow significantly, indicating a strong trend toward sustainable manufacturing practices. This shift is being propelled by innovations in servo motors which not only enhance performance but also reduce energy consumption. As industries seek to optimize their operations, the integration of servo technologies becomes paramount, enabling manufacturers to achieve higher productivity with lower operational costs.

In particular, the implementation of advanced servo-electric drives in machinery is transforming traditional processes. These technologies offer precise control over speed and torque, leading to minimized energy wastage. An example can be observed in the injection molding sector, where state-of-the-art servo-electric drive systems are streamlining production and ensuring better material utilization. The anticipated growth in the digital servo motors and drives market underscores the industry's commitment to leveraging these technologies to drive efficiencies that are both economically and environmentally beneficial.

Integrating Smart Technology for Real-Time Performance Monitoring

The integration of smart technology in industrial automation has revolutionized performance monitoring in manufacturing. Real-time data collection from servo motors enables manufacturers to gain insights into operational efficiencies, identifying areas for optimization and reducing downtime. With the ability to monitor the performance of machinery instantly, manufacturers can make informed decisions to enhance production processes, leading to improved reliability and reduced costs.

As industries increasingly adopt artificial intelligence and IoT-based solutions, real-time performance monitoring becomes even more critical. These technologies allow for continuous feedback loops, enabling predictive maintenance and reducing the risk of unexpected failures. In the context of China's manufacturing sector, this transition towards smarter practices not only enhances productivity but also aligns with the broader vision of digital transformation, providing the foundation for sustainable growth and innovation in an increasingly competitive global market.

Unlocking Efficiency: Industrial Servo Motor Performance Comparison

This bar chart illustrates the efficiency percentages of different types of industrial servo motors in manufacturing automation over a specific period, showcasing their impact on real-time performance monitoring.

Future Trends: The Role of Servo Motors in Next-Gen Manufacturing Solutions

As industries evolve, the role of servo motors in manufacturing becomes increasingly critical. These precise and efficient components drive the automation of machinery, allowing for high-speed production with minimal waste. The future of manufacturing solutions is expected to heavily rely on advanced servo motor technology, integrating smart features such as real-time monitoring and adaptive control. This enables manufacturers to enhance productivity and reduce downtime, ultimately leading to a more streamlined operation.

Tip: When implementing servo motors, focus on selecting the right drive systems and feedback devices to ensure optimal performance. Investing in compatible and advanced controller algorithms can significantly increase the responsiveness and accuracy of your automation systems.

Trends indicate that servo motors will play a pivotal role in next-gen manufacturing solutions, especially with the rise of Industry 4.0. These motors can seamlessly connect to IoT systems, providing valuable data insights that enable predictive maintenance and enhance overall efficiency. By harnessing these capabilities, companies can adapt more swiftly to market demands and maintain a competitive edge.

Tip: Regularly calibrate and maintain your servo motors to ensure they perform at their best. Keeping up with technological advancements in servo motor design will also give your production facility a modern edge.

Related Posts

-

Top Strategies for Maximizing Performance with Best AC Servo Drives

-

Explore the Technical Specifications of the Best Servo Drives and How to Choose the Right One for Your Needs

-

Overcoming Common Challenges with Servo Motors: A Deep Dive into Performance and Reliability Issues

-

Understanding the Advantages of Integrated Servo Motors in Modern Automation

-

Electric Servo Motor Showdown: Which Type Reigns Supreme in Performance and Efficiency?

-

7 Essential Tips for Maximizing Performance with AC Servo Motors