Why Choose a DC Servo Drive for Your Industrial Automation Needs

In today's rapidly evolving industrial landscape, the demand for precise control and efficiency in automation processes has never been greater. Among the various technologies available to meet these requirements, the dc servo drive stands out as a premier choice for industrial automation needs. This advanced drive system not only enhances the performance of automation applications but also improves overall productivity and operational reliability.

DC servo drives are recognized for their ability to deliver high torque, fast response times, and exceptional accuracy, making them ideal for a plethora of applications ranging from robotics to conveyor systems. The integration of dc servo drives in automation solutions enables manufacturers to achieve finer control over their processes, leading to increased output quality and reduced downtime. As industries strive to enhance their competitive edge, understanding the benefits and functionalities of dc servo drives becomes essential for decision-makers looking to optimize their automation systems.

In this exploration of why dc servo drives are an invaluable asset for industrial automation, we will delve into their operational advantages, key features, and the role they play in streamlining processes. By harnessing the power of dc servo drives, businesses can not only elevate their automation capabilities but also drive innovation and sustainability in their operations.

Understanding DC Servo Drives in Industrial Automation

DC servo drives are crucial components in industrial automation, enabling precise control over motion and speed in various applications. These drives integrate a direct current (DC) motor with a feedback system to ensure accurate and responsive operation. By continuously monitoring the motor’s performance, DC servo drives can make real-time adjustments to maintain desired speed and position, making them ideal for scenarios that require high precision.

Tips: When selecting a DC servo drive, consider the load requirements and the operating environment. Ensure the drive can handle the acceleration and deceleration rates needed for your application while providing sufficient torque. Additionally, think about the connectivity options available, as this will affect how well the drive can integrate with your existing systems.

In industrial settings, the application of DC servo drives can improve efficiency and productivity. Tasks such as CNC machining, robotic arms, and conveyor systems benefit from the smooth and controlled movements that these drives offer. Their ability to maintain consistent performance under varying loads is a key reason why they are favored in automation processes across industries.

Tips: Regular maintenance of DC servo systems is essential to prolong their lifespan. Monitor temperature and vibrations, and ensure that feedback components are functioning correctly to prevent unexpected downtime and costly repairs.

Why Choose a DC Servo Drive for Your Industrial Automation Needs

| Feature | Description | Benefits |

|---|---|---|

| High Precision | DC servo drives provide precise control over speed and position. | Ideal for applications requiring accurate movement. |

| Fast Response Time | Offers quick torque and speed adjustments. | Enhances performance in dynamic applications. |

| Compact Size | Smaller footprint compared to AC systems. | Saves space in control panels and machinery. |

| Energy Efficiency | Better energy consumption rates during operation. | Reduces overall operating costs. |

| Ease of Integration | Compatible with various control systems and devices. | Simplifies system upgrades and expansions. |

| Robust Performance | Designed to withstand harsh industrial environments. | Increases reliability and reduces downtime. |

Key Advantages of Using DC Servo Drives

DC servo drives are an essential component in modern industrial automation, offering distinct advantages that enhance system performance and reliability. One of the primary benefits of using DC servo drives is their impressive precision and control. These drives allow for fine-tuned speed and position control, making them ideal for applications that require high levels of accuracy, such as robotics and CNC machines. With the ability to respond quickly to commands, DC servo drives ensure that processes run smoothly and efficiently, minimizing downtime and improving overall productivity.

Another significant advantage of DC servo drives is their excellent torque characteristics. They can provide high torque at low speeds, which is particularly beneficial for applications requiring heavy lifting or intricate movements. This capability not only enhances the operational efficiency but also extends the life of machines by reducing the strain on mechanical components. Moreover, the simplicity of integrating DC servo drives into existing systems makes them a convenient choice for upgrading automation processes without extensive modifications. The robustness and reliability of these drives further contribute to their popularity in various industrial sectors, where performance consistency is crucial for business success.

Comparison of DC Servo Drives with Other Drive Types

When considering industrial automation solutions, DC servo drives stand out against other types of drive systems, notably AC servo drives and stepper motors. A report by the International Society of Automation highlights that DC servo drives typically offer superior precision and responsiveness, making them ideal for applications requiring high accuracy. Their ability to deliver high torque at low speeds, combined with quick acceleration capabilities, enables them to excel in tasks such as robotic assembly and CNC machining, where fine control is paramount.

In contrast, while AC servo drives are often favored for their robustness and efficiency in high-power applications, they may not achieve the same level of responsiveness as DC servo drives. According to a recent study by the National Institutes of Standards and Technology, DC servo drives can exhibit up to 25% faster response times in dynamic applications. Additionally, unlike stepper motors, which can experience resonance and reduced performance at higher speeds, DC servo drives maintain their performance across a broader range of operational conditions. The distinct advantages of DC servo drives in both precision and speed are key factors driving their adoption in modern industrial automation systems.

Comparison of DC Servo Drives with Other Drive Types

Applications of DC Servo Drives in Various Industries

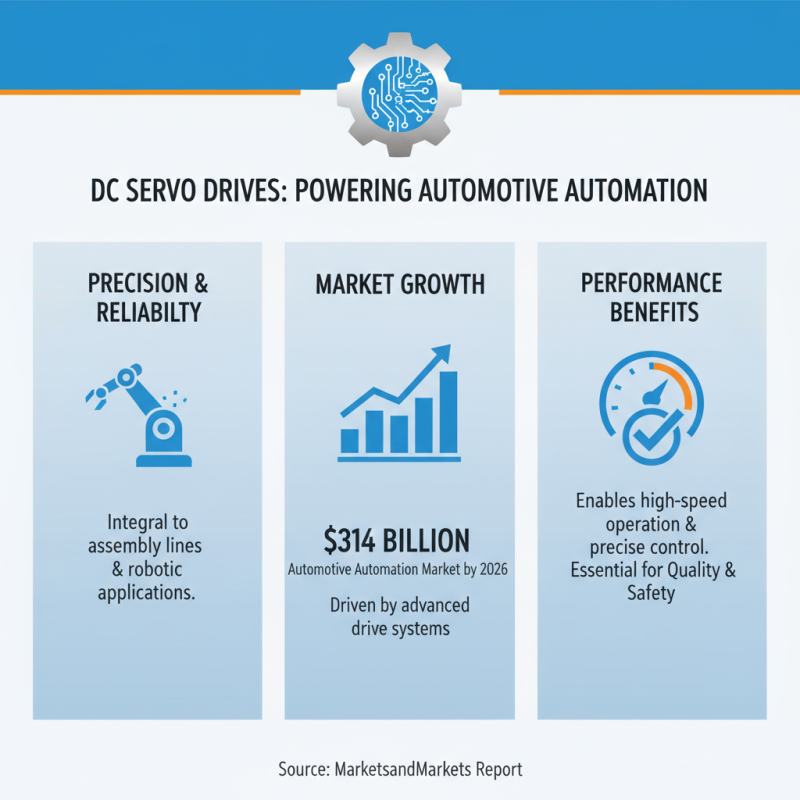

DC servo drives have become increasingly pivotal in various industrial sectors due to their precision, reliability, and efficiency. In the automotive industry, for instance, DC servo drives are integral to automation systems used for assembly lines and robotic applications. A report by MarketsandMarkets estimates that the automotive automation market will reach $314 billion by 2026, with a significant portion attributable to enhanced drive systems like DC servos. These systems enable high-speed operation and precise control, essential for meeting the increasing demands for quality and safety in automotive production.

In the packaging industry, DC servo drives facilitate faster and more accurate packaging processes. According to a study by Grand View Research, the global packaging automation market is expected to reach $59.6 billion by 2025. Servo drives play a key role in applications ranging from bottle filling to carton sealing. Their ability to provide consistent performance and reduce downtime translates not only into cost savings but also into improved throughput. By minimizing errors and increasing speed, DC servo drives help manufacturers meet the rigorous timelines and standards required in high-volume production environments.

Similarly, in the semiconductor manufacturing sector, DC servo drives are essential for precision handling and manufacturing processes. The semiconductor equipment market is projected to grow at a CAGR of 7.2% from 2020 to 2027, underscoring the need for advanced automation technologies. DC servo drives enhance equipment performance, enabling accurate movements and controlling complex manufacturing processes required for chip fabrication. With the industry pushing towards smaller, more complex devices, the role of DC servo drives in ensuring efficiency and precision cannot be overstated.

Factors to Consider When Selecting a DC Servo Drive

When selecting a DC servo drive for industrial automation applications, several critical factors must be considered to ensure optimal performance and compatibility with your systems. Firstly, the torque and speed requirements of your specific machinery play a vital role. According to a report by MarketsandMarkets, the global servo motor market size is expected to grow from USD 8.3 billion in 2020 to USD 12.9 billion by 2025, indicating an increasing need for devices that can handle varying operational demands efficiently. Assessing the load characteristics, such as inertia and friction, alongside desired acceleration profiles, will help in determining the appropriate specifications for the servo drive.

Another key factor to consider is the integration and compatibility of the DC servo drive with existing controls and software systems. The Industrial Internet of Things (IIoT) has driven the demand for smart solutions that provide real-time monitoring and data analysis capabilities. A study from Statista indicates that by 2025, the number of connected IoT devices in industrial settings could exceed 75 billion, thereby emphasizing the need for servo drives that can easily interface with these networks. Furthermore, it is crucial to account for feedback mechanisms, such as encoders, to achieve the necessary precision and responsiveness in dynamic applications. This comprehensive approach ensures that the selected DC servo drive aligns seamlessly with both current and future automation goals.

Related Posts

-

Advanced Solutions for Enhancing Efficiency with Hollow Shaft Servo Motors

-

Understanding the Fundamentals of AC Servo Technology: What You Need to Know

-

Understanding the Benefits of AC Servo Drives in Modern Automation Systems

-

Addressing Common Calamities in High Torque Motor Procurement: A Global Perspective

-

Explore the Technical Specifications of the Best Servo Drives and How to Choose the Right One for Your Needs

-

How to Choose the Right Industrial Servo Motor for Your Application