5 Best Ways to Optimize Motor Power for Industrial Efficiency

In the pursuit of enhanced industrial efficiency, optimizing motor power has emerged as a crucial factor that can significantly affect operational costs and productivity levels. According to a report by the International Energy Agency, electric motors account for nearly 70% of industrial electricity consumption, indicating a substantial opportunity for energy savings through effective motor power management. By leveraging advanced technologies and implementing strategic practices, industries can not only reduce energy expenses but also improve their overall environmental footprint. In fact, a well-optimized motor system can lead to energy savings of up to 30%, underscoring the importance of focusing on motor power optimization. This blog will explore the five best ways to harness motor power for peak industrial efficiency, providing actionable insights for businesses aiming to stay competitive in today's energy-conscious market.

Understanding Motor Power: The Key to Industrial Efficiency

Understanding motor power is crucial for enhancing industrial efficiency. With the right motor systems in place, industries can significantly reduce energy consumption and operational costs. Efficient motors and variable-speed drives (VSDs) have the potential to lower global energy usage by as much as 10%. This is not just a theoretical benefit; it represents a substantial opportunity for companies looking to optimize their energy use without compromising performance.

Recent advancements in motor technology, such as the introduction of high-efficiency motors, further support this initiative. Companies are investing significantly to modernize their motor manufacturing capabilities and embrace more energy-efficient solutions. Large motors designed with energy conservation in mind promise significant potential savings over their lifespan, leading to increased industrial efficiency. Thus, prioritizing motor power optimization is not only an environmental imperative but also a strategic business decision for future sustainability and cost-effectiveness.

Assessing Your Current Motor Power Requirements for Optimal Use

Assessing your current motor power requirements is crucial for achieving optimal industrial efficiency. According to the U.S. Department of Energy, electric motors account for approximately 65% of the industrial electrical consumption. Understanding the specific power needs of your operations can lead to significant energy savings and improved performance. To start, conduct a comprehensive audit of your motor systems to identify underperforming units and assess their load profiles.

Tip: Implement a real-time monitoring system to track motor performance and energy consumption. This data can offer insights into inefficiencies and help adjust operational practices accordingly.

Moreover, it's essential to compare your motor power requirements against industry benchmarks. Recent reports indicate that companies optimizing their motor systems can realize energy savings of up to 30%. By evaluating existing motors and aligning them with their typical load conditions, industrial facilities can boost productivity while reducing waste.

Tip: Consider upgrading to high-efficiency motors that comply with the latest regulations, as these can provide return on investment through lower energy costs over time.

Implementing Advanced Control Systems for Enhanced Motor Performance

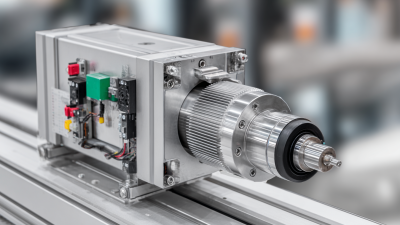

Implementing advanced control systems is crucial for optimizing motor power in industrial settings. These systems incorporate sophisticated algorithms and real-time data to fine-tune motor performance according to varying operational conditions. By using technologies such as variable frequency drives (VFDs) and soft starters, industries can precisely control motor speed and torque, leading to significant energy savings and improved reliability. This precision not only enhances the overall efficiency of machinery but also reduces wear and tear, extending the lifecycle of the equipment.

In addition to VFDs, the integration of smart sensors and IoT technology allows for continuous monitoring of motor performance. These sensors provide valuable insights into operational parameters such as temperature, vibration, and load, enabling predictive maintenance strategies. By analyzing this data, industrial operators can identify inefficiencies and make real-time adjustments to optimize motor power. As a result, advanced control systems not only streamline operations but also contribute to sustainable practices by minimizing energy consumption and enhancing productivity.

Regular Maintenance Practices to Maximize Motor Longevity and Efficiency

Regular maintenance practices are essential for maximizing the longevity and efficiency of motors in industrial settings. By adhering to a scheduled maintenance program, facilities can prevent unexpected downtime caused by motor failures. This includes routine inspections where bearings, shafts, and electrical connections are checked for wear and tear. Monitoring vibration levels and temperature can also provide critical insights into potential issues before they escalate.

In addition to inspections, lubricating moving parts and keeping motors clean from dust and contaminants can significantly enhance performance. Proper alignment of motors with connected equipment further ensures that energy is not wasted due to friction or misalignment. Implementing these maintenance practices not only extends the life of the motors but also optimizes their power usage, contributing to overall industrial efficiency. By treating motor maintenance as a priority rather than a mere afterthought, businesses can achieve higher productivity and reduce operational costs.

Utilizing Energy Recovery Systems to Reduce Power Waste in Operations

Energy recovery systems play a crucial role in optimizing motor power within industrial operations, significantly reducing power waste and enhancing overall efficiency. By harnessing excess energy generated during various processes—such as braking in machinery or heat produced in motors—these systems can convert and reuse this energy for other operational needs. This not only minimizes energy loss but also lowers operational costs, contributing to a more sustainable industrial environment.

Implementing energy recovery systems can come in various forms, such as regenerative braking systems in conveyors and lift systems or heat exchangers that capture waste heat. These technologies not only extend the life of equipment by reducing wear and tear but also provide a quick return on investment through reduced energy bills. As industries strive for sustainability and operational excellence, energy recovery is becoming an indispensable strategy for optimizing motor power while aligning with environmental goals.

Related Posts

-

Understanding the Advantages of Integrated Servo Motors in Modern Automation

-

Advanced Solutions for Enhancing Efficiency with Hollow Shaft Servo Motors

-

7 Reasons Why Your Factory Needs an AC Servo Motor Today

-

7 Essential Tips for Maximizing Performance with AC Servo Motors

-

Explore the Technical Specifications of the Best Servo Drives and How to Choose the Right One for Your Needs

-

Overcoming Common Challenges with Servo Motors: A Deep Dive into Performance and Reliability Issues