Top 10 Benefits of Using DC Servomotors in Modern Automation Systems

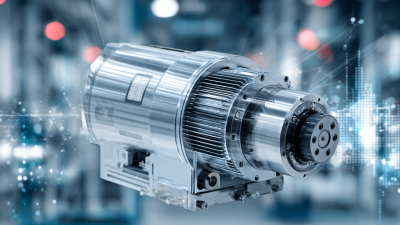

In today's rapidly evolving industrial landscape, the demand for precision and efficiency in automation systems has never been higher. A crucial component that stands at the forefront of this technological revolution is the DC servomotor. According to a report by Research and Markets, the global servomotor market is projected to reach $13.35 billion by 2025, growing at a CAGR of 7.3%. This growth is driven by the increasing adoption of automation in various industries, including manufacturing, robotics, and aerospace. The versatility and performance of DC servomotors make them an ideal choice for applications requiring high responsiveness and precise control.

DC servomotors offer numerous advantages that enhance overall system performance and efficiency. Their ability to provide accurate position control, high torque at low speeds, and rapid acceleration and deceleration can significantly improve production times and reduce operational costs. Furthermore, with advancements in power electronics and control algorithms, these motors are becoming even more reliable and energy-efficient, catering to the growing demand for sustainable automation solutions. As industries look to optimize their operations and embrace smart manufacturing processes, the role of DC servomotors is set to become increasingly vital, shaping the future of modern automation systems.

Benefits of Enhanced Precision in DC Servomotors for Automation

DC servomotors are revolutionizing modern automation systems, particularly with enhanced precision that is essential for high-stakes industries such as manufacturing and robotics. According to a report by the International Society of Automation, the global market for servomotors is projected to reach $13.17 billion by 2025, highlighting a growing demand for precision-driven technologies. The superior control and accuracy provided by DC servomotors enable machines to operate at optimal efficiency, reducing error margins and increasing overall productivity. This level of precision can lead to a significant reduction in waste, translating into up to a 20% decrease in operational costs.

Tips: When selecting a servomotor for your application, consider the type of feedback mechanism—such as encoders or resolvers—used in conjunction with DC servomotors. This can further enhance precision and control in complex automation tasks.

Moreover, the enhanced torque and speed characteristics of DC servomotors contribute to their usability in various automation scenarios. Studies indicate that applications utilizing DC servomotors can achieve up to 30% faster cycle times compared to traditional motors, making them ideal for high throughput operations. This acceleration not only boosts production capabilities but also allows for more flexible manufacturing processes capable of adapting to changing demands in the market.

Tips: Regular maintenance of servomotors is crucial for preserving their precision. It is recommended to implement a scheduled maintenance routine to check for wear and tear, ensuring long-lasting performance and reliability in your automation setup.

Top 10 Benefits of Using DC Servomotors in Modern Automation Systems

| Benefit | Description | Impact on Automation |

|---|---|---|

| Enhanced Precision | DC servomotors provide high accuracy in position control. | Enables complex automation tasks with high repeatability. |

| Fast Response Time | DC servomotors can quickly change speeds and directions. | Improves overall system performance in dynamic applications. |

| Compact Size | Small footprint allows for integration into tight spaces. | Facilitates design flexibility in automation systems. |

| Energy Efficiency | Lower power consumption compared to traditional motors. | Reduces operating costs and environmental impact. |

| Robust Control Algorithm | Advanced feedback mechanisms for superior control. | Ensures stable operation in varying conditions. |

| Reduced Maintenance | Fewer mechanical parts lead to lower wear and tear. | Increases uptime and overall system reliability. |

| High Torque Density | Generates more torque in a smaller size. | Improves performance in compact systems. |

| Versatile Applications | Suitable for various industries and processes. | Enhances the adaptability of automation solutions. |

| Minimal Noise Generation | Operates more quietly than traditional motors. | Improves work environment and user experience. |

| Improved Safety Features | Incorporates advanced safety protocols. | Enhances operational safety in automation systems. |

Improved Speed Control and Responsiveness in Modern Systems

DC servomotors have revolutionized the landscape of modern automation systems, particularly when it comes to enhanced speed control and responsiveness. These motors are designed to provide precise control over velocity and position, making them ideal for applications requiring quick adjustments. Their ability to change speed rapidly allows for smoother operation and better performance in dynamic environments, where rapid response time can be crucial for system efficiency and productivity.

In modern automation, the integration of DC servomotors leads to significant improvements in overall system performance. Their advanced feedback mechanisms enable real-time adjustments, ensuring that the motor can react instantly to changes in load or speed requirements. This responsiveness minimizes lag and optimizes system throughput, enabling manufacturers to achieve higher levels of accuracy in tasks such as machining, robotics, and conveyor operations. By leveraging their enhanced capabilities, industries can not only improve their operational efficiency but also enhance product quality through precise execution and control.

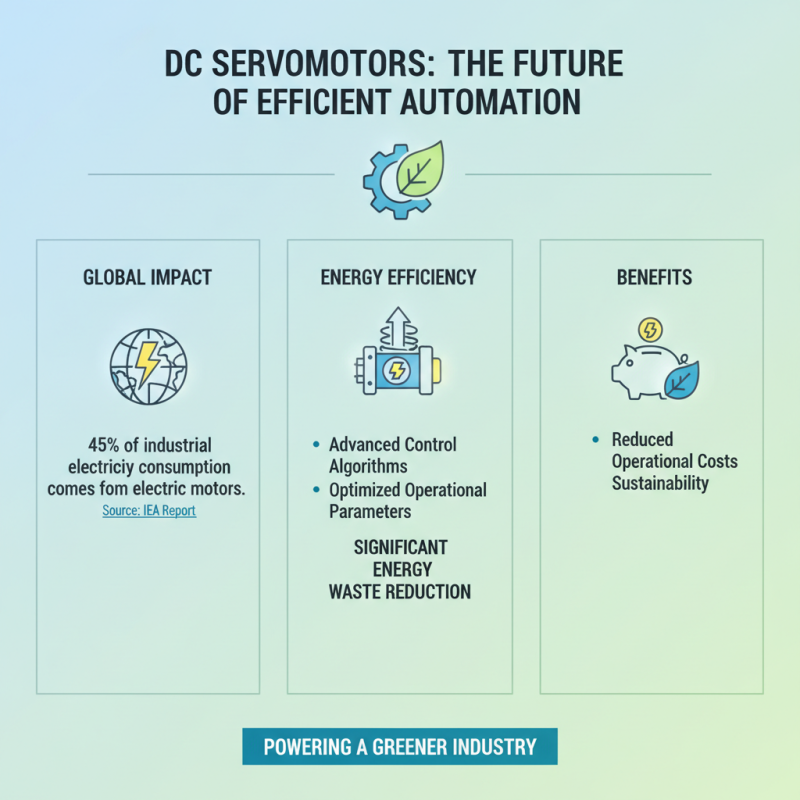

Energy Efficiency Advantages of DC Servomotors in Automation

In recent years, DC servomotors have emerged as pivotal components in modern automation systems, primarily due to their superior energy efficiency. According to a report by the International Energy Agency, electric motors—including DC servomotors—account for approximately 45% of global electricity consumption in industrial applications. By employing advanced control algorithms and optimizing the motor's operational parameters, DC servomotors can significantly reduce energy waste, leading to a remarkable potential for reducing operational costs and enhancing sustainability.

One of the key energy efficiency advantages of DC servomotors lies in their ability to deliver precise control over speed and torque with minimal power loss. This precision allows for adjustments to be made in real-time, optimizing performance based on specific process requirements. A study published in the journal "Energy Efficiency" indicates that implementing DC servomotors can result in energy savings of 20-30% compared to traditional AC motors in similar applications. Furthermore, their compact design and lightweight construction contribute to reduced energy consumption during operation, making them an ideal choice for applications in sectors such as automotive, manufacturing, and robotics. As industries increasingly focus on sustainability and reducing their carbon footprint, the role of energy-efficient solutions like DC servomotors is becoming increasingly critical.

Versatile Applications of DC Servomotors in Various Industries

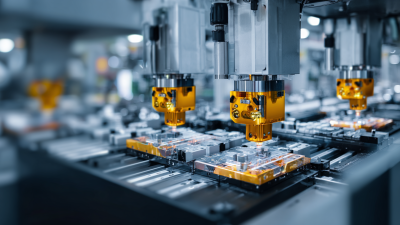

DC servomotors have become fundamental components in modern automation systems, delivering precision control and reliability across numerous industries. According to a report by Market Research Future, the global DC servomotor market is expected to reach $7 billion by 2025, driven by the increasing automation in manufacturing processes. These motors are widely utilized in applications such as robotics, conveyor systems, and CNC machinery, where precise positioning and speed control are paramount.

One of the notable advantages of DC servomotors is their versatility in various industrial settings. In the automotive industry, for example, DC servomotors are employed in assembly lines to ensure accurate assembly of parts and enhance production efficiency. Similarly, in the aerospace sector, they play a crucial role in controlling flight control surfaces and landing gear mechanisms. The capability of these motors to deliver high torque at low speeds makes them ideal for applications requiring smooth and accurate movements. Furthermore, the increasing demand for electric vehicles is anticipated to further expand the application of DC servomotors in automotive designs, as confirmed by industry forecasts expecting electric vehicle sales to reach over 30 million units by 2030.

In the packaging sector, DC servomotors are integral to automated systems for high-speed operations, allowing for quick adjustments and enhanced productivity. The versatility of these motors to easily integrate with advanced automation technologies, such as machine vision and IoT, positions them as a key asset in the evolving landscape of industrial automation. Such trends highlight the vital role that DC servomotors will continue to play in optimizing efficiency and performance across diverse applications.

Simplified Integration and Maintenance of DC Servomotors

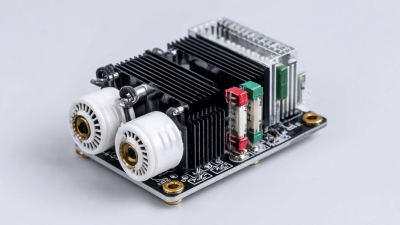

The integration of DC servomotors in modern automation systems offers a streamlined approach to both installation and maintenance, making them an attractive choice for industries seeking efficiency and reliability. With their compact design and easy-to-use interfaces, DC servomotors can be seamlessly incorporated into existing systems without the need for extensive reconfiguration. This compatibility allows for quicker project turnaround times and minimizes disruption to ongoing operations.

Maintenance of DC servomotors is equally straightforward, thanks in part to their robust design and the availability of diagnostic tools. Routine checks and calibrations can often be performed without specialized training, empowering in-house teams to handle regular upkeep. This reduces downtime and potential costs associated with hiring external technicians, contributing to a more streamlined maintenance process.

Tips: When integrating DC servomotors, always ensure that your system includes an easily accessible control interface. This will not only facilitate smoother operation but will also provide a point for quick diagnostics. Additionally, consider developing a maintenance schedule that aligns with your overall operational plan; addressing small issues proactively can prevent larger, more costly problems down the line.

Top 10 Benefits of Using DC Servomotors in Modern Automation Systems

This bar chart illustrates the top 10 benefits of using DC servomotors in modern automation systems, rated on a scale from 1 to 10 based on their importance. The data shows that high efficiency and simplified integration are among the most valued characteristics.

Related Posts

-

Explore the Technical Specifications of the Best Servo Drives and How to Choose the Right One for Your Needs

-

7 Reasons Why High Torque Motors Are Revolutionizing Industrial Applications

-

Electric Servo Motor Showdown: Which Type Reigns Supreme in Performance and Efficiency?

-

Unlocking Efficiency: How Industrial Servo Motors Transform Automation in Manufacturing

-

Exploring the Future of DC Servomotors at the 138th Canton Fair 2025: Industry Trends and Insights

-

Future Trends in Technology 2025 How to Choose the Best Servo Amplifier for Your Applications