Top 10 Benefits of Using DC Servo Drives in Industrial Applications

In the rapidly advancing landscape of industrial automation, the adoption of innovative technologies has become paramount for enhancing operational efficiency and productivity. One such technology that has gained significant traction is the dc servo drive. Known for its precise control and reliability, the dc servo drive offers a plethora of advantages that are transforming the way industries operate. With applications ranging from robotics to conveyor systems, the versatility of dc servo drives is unmatched, allowing for superior performance in demanding environments.

This article delves into the top 10 benefits of utilizing dc servo drives in industrial applications. By focusing on elements such as enhanced speed control, increased energy efficiency, and improved system responsiveness, we will explore how these drives not only streamline processes but also contribute to significant cost savings over time. As industries continue to seek ways to optimize their operations, understanding the transformative impact of dc servo drives becomes crucial. This exploration aims to provide insights into why incorporating dc servo drives can be a game-changer for industrial operations, ultimately leading to smarter, more efficient manufacturing solutions.

Overview of DC Servo Drives and Their Functionality

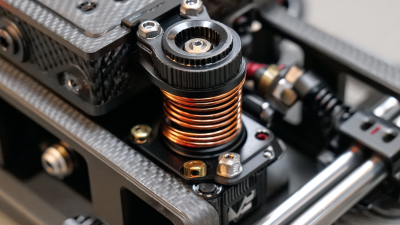

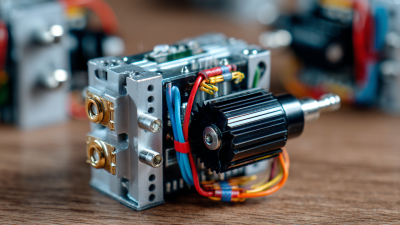

DC servo drives are essential components in various industrial applications, providing precise control over motion and speed. They function by using a direct current (DC) motor combined with a feedback control loop, enabling accurate positioning and velocity management. This closed-loop system continuously monitors the motor's output and makes real-time adjustments, ensuring optimal performance. The ability to control torque, speed, and position meticulously makes DC servo drives suitable for tasks that require high levels of precision, such as robotics, CNC machines, and conveyor systems.

**Tip:** To maximize efficiency, ensure that your DC servo drive is appropriately matched to the application requirements, including load characteristics and desired response time. Proper sizing and selection can significantly enhance the system's performance and longevity.

Another advantage of DC servo drives is their adaptability in various environments. With a solid design, these drives can operate in settings with heavy dust, moisture, or temperature fluctuations. Additionally, their compact size and lightweight construction contribute to space-saving designs in equipment layouts.

**Tip:** Regular maintenance of DC servo drives is crucial for sustaining performance. Implement a routine check to inspect wiring connections, cleanliness, and lubrication of moving parts to prevent unforeseen downtime.

Top 10 Benefits of Using DC Servo Drives in Industrial Applications

DC Servo Drives offer a wide range of benefits for industrial applications. This chart illustrates the score of each benefit based on their importance and effectiveness in enhancing performance, efficiency, and reliability in various operations.

Key Advantages of Enhanced Precision in Industrial Applications

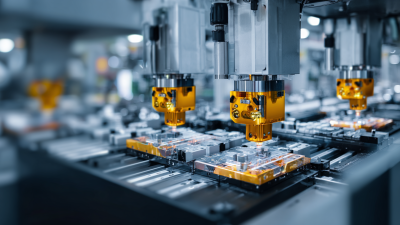

In industrial applications, precision is paramount, and DC servo drives are an excellent solution for achieving enhanced accuracy in operations. One of the key advantages of using DC servo drives is their ability to provide precise control of position, speed, and torque. This precision enables manufacturers to enhance the quality of their products while minimizing waste and reducing errors during production processes. By employing these drives, industries can optimize their machinery for tasks that require meticulous attention to detail, such as robotic arms in assembly lines.

Tips: When integrating DC servo drives into your operations, consider conducting thorough training sessions for your team. Familiarity with the drive’s features can significantly improve the overall efficiency of your production line.

Another benefit of DC servo drives is their response time, which is crucial for dynamic industrial environments. These drives can adjust quickly to changes in load conditions and operational demands, ensuring that production remains uninterrupted. The fast response also enhances the system’s ability to maintain consistent performance, ultimately leading to improved output rates and reduced cycle times. Industries that leverage this technology can enjoy not only better production efficiency but also increased responsiveness to market demands.

Tips: Regular maintenance of DC servo drives can sustain their high performance. Create a preventative maintenance schedule to identify potential issues before they affect productivity.

Top 10 Benefits of Using DC Servo Drives in Industrial Applications

| Benefit | Description | Impact on Efficiency |

|---|---|---|

| Enhanced Precision | DC servo drives provide high accuracy in positioning and speed control. | Increased product quality and reduced waste. |

| Improved Control | Offers advanced control algorithms for better performance. | Enhanced operational efficiency and response time. |

| Higher Speed | Supports high-speed applications with rapid acceleration and deceleration. | Reduced cycle time and increased output. |

| Energy Efficiency | DC servo drives can optimize energy consumption during operation. | Lower operating costs and reduced environmental impact. |

| Compact Design | Smaller footprint compared to AC drives allows for space-saving installations. | Easier integration into existing systems. |

| Reliable Performance | DC servo drives provide consistent and reliable output under various conditions. | Decreased downtime and maintenance costs. |

| Flexibility | Can be easily configured for various applications and requirements. | Adaptable to changing production needs. |

| Lower Noise Operation | Reduced noise levels compared to traditional systems. | Improved workplace environment and ergonomics. |

| Ease of Programming | User-friendly programming interfaces for setup and operation. | Quicker setup times and less training needed for operators. |

| Cost-Effective Solutions | In the long run, DC servo drives lead to lower total cost of ownership. | Maximized ROI through increased productivity. |

Energy Efficiency Improvements with DC Servo Drives

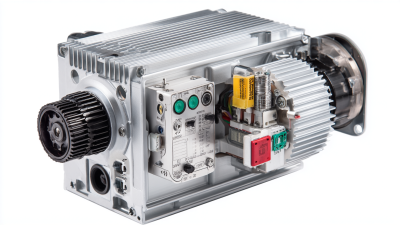

The integration of DC servo drives in industrial applications has been heralded for its substantial improvements in energy efficiency. Recent studies indicate that these drives can enhance energy utilization by as much as 30% compared to traditional AC motors, providing a compelling case for manufacturers eager to reduce operational costs. This increase in efficiency is largely attributed to the precise control over torque and speed that DC servo drives offer, allowing for optimal performance in a wide range of conditions.

Moreover, a report from the Global Energy Management Association highlights that the implementation of advanced control algorithms in DC servo systems leads to significant reductions in energy consumption during varying load conditions. The capability of DC servo drives to adjust their power usage dynamically results in lower electrical demand and minimizes wasted energy. This adaptation not only supports sustainable practices but also helps organizations meet their energy-saving targets, which are increasingly becoming a priority in industrial sectors worldwide. Therefore, adopting DC servo drives is not only a step towards modernization but also a significant move towards achieving greater energy efficiency in manufacturing processes.

Reduced Maintenance Costs and Increased Reliability

In industrial applications, the use of DC servo drives has demonstrated significant advantages, particularly in terms of reduced maintenance costs and increased reliability. One of the key factors contributing to lower maintenance expenses is the elimination of mechanical components typically found in traditional systems. According to a report by the International Society of Automation, systems utilizing DC servo drives can reduce mechanical wear and tear significantly, cutting maintenance costs by as much as 30%. The absence of gears and belts in many DC servo configurations diminishes the frequency of required servicing, which not only saves money but also enhances operational uptime.

Moreover, DC servo drives excel in providing reliable performance in demanding environments. A study by the National Institute of Standards and Technology indicates that industries leveraging advanced motion control technologies, like DC servo drives, report a 25% increase in overall system reliability compared to older drive technologies. This increase can be attributed to the precise control and feedback mechanisms inherent in DC servo systems, which help maintain consistent performance levels and minimize the risk of failure. As a result, companies can achieve higher production rates and greater process stability, further solidifying the case for adopting DC servo drives in the industrial sector.

Versatility and Adaptability Across Various Industrial Environments

DC servo drives have gained significant traction in various industrial applications due to their remarkable versatility and adaptability. These systems operate efficiently across different environments, making them suitable for a wide array of tasks, from CNC machinery to robotics and packaging lines. Their ability to provide precise control over speed and position allows industries to achieve high levels of accuracy and repeatability, essential for maintaining quality standards.

Tips for maximizing the benefits of DC servo drives include ensuring proper system integration to harness their full potential. Pay attention to the compatibility of components, such as feedback devices and controllers, to ensure seamless communication within the system. Additionally, regular maintenance checks can prevent unexpected downtimes, increasing operational efficiency.

Another essential aspect is choosing the right specifications for your application. Consider factors such as load requirements, response times, and environmental conditions. Whether in a climate-controlled setting or a more challenging environment, DC servo drives can be tailored to meet the specific demands of the task at hand. By evaluating these factors carefully, industries can leverage the full capabilities of DC servo drives while enhancing productivity and performance.

Related Posts

-

7 Essential Tips for Choosing the Best High Torque Servo Based on Performance Data

-

Unlocking Efficiency: How Industrial Servo Motors Transform Automation in Manufacturing

-

2025 Guide: How to Choose the Best Small Servo Motor for Your Robotics Project

-

Why Choose Small Servo Motors for Your Next Project? Benefits and Applications Explained!

-

Understanding the Advantages of AC Servo Drives in Modern Automation Solutions

-

Understanding the Fundamentals of AC Servo Technology: What You Need to Know