Understanding the Benefits of AC Servo Drives in Modern Automation Systems

In the rapidly evolving landscape of automation systems, the adoption of AC servo drives has emerged as a pivotal trend, significantly enhancing operational efficiency and precision. According to a report by MarketsandMarkets, the global AC servo drive market is projected to reach USD 12.24 billion by 2026, growing at a CAGR of 7.3% from 2021. This growth is driven by the increasing demand for high-performance motors in various industries, including manufacturing, automotive, and electronics. The ability of AC servo drives to deliver superior speed control and enhanced torque responsiveness makes them indispensable in modern automation processes.

Industry expert Dr. John Stevens, a leading authority on servo technology, asserts, "The integration of AC servo drives into automation systems not only increases productivity but also improves accuracy across a range of applications." His insights emphasize the critical role that AC servo drives play in reducing downtime and waste, thereby offering substantial cost savings for companies. As industries continue to prioritize automation, understanding the multifaceted benefits of AC servo drives will be essential for businesses aiming to remain competitive in an increasingly automated world.

Enhancing Precision Control: The Role of AC Servo Drives in Automation

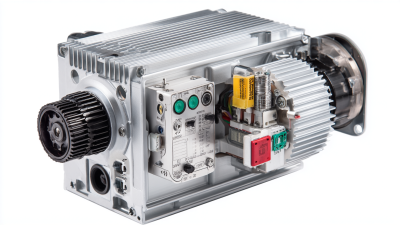

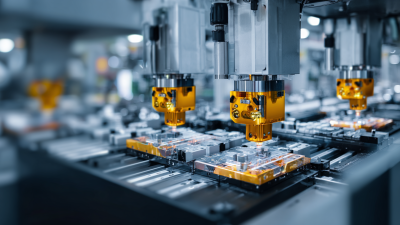

AC servo drives have revolutionized automation systems by providing unparalleled precision control. These systems allow for highly accurate positioning of motors, which is essential in applications ranging from robotics to CNC machining. The ability to finely tune the servo drive parameters enables engineers to achieve outstanding performance, improving both speed and efficiency in manufacturing processes. This precision facilitates complex tasks to be executed with minimal error, ultimately enhancing the quality of the final product.

**Tip:** When selecting an AC servo drive, consider the specific requirements of your application, such as load characteristics and desired speed performance. Matching the servo drive with the appropriate motor type and feedback system is crucial for optimal performance.

Moreover, the adaptability of AC servo drives in various automation environments makes them a preferred choice. They can easily integrate with existing systems and support various communication protocols, leading to a more streamlined operation. The flexibility in controlling torque, speed, and position allows businesses to respond quickly to changing production demands, saving both time and resources.

**Tip:** Regularly update the control algorithms of your AC servo drives to benefit from the latest advancements in automation technology. This will help maintain efficiency and accuracy in your operations.

Energy Efficiency Gains: How AC Servo Drives Reduce Operational Costs

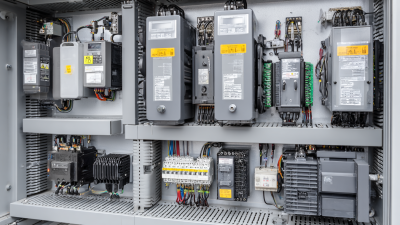

AC servo drives have emerged as pivotal components in modern automation systems, primarily due to their significant energy efficiency gains. These drives are designed to provide precise control over motor performance, which not only enhances operational effectiveness but also leads to substantial reductions in energy consumption. By optimizing the power used during operations, businesses can effectively lower their operational costs, making AC servo drives an attractive choice for manufacturers seeking to improve their bottom line while also contributing to sustainability initiatives.

The growing shift towards automation across various industries, including automotive and manufacturing, further underscores the importance of AC servo drives. Market analyses indicate that the global AC servo motors and drives market was valued at USD 15.2 billion in 2024, with projections suggesting a 6.6% growth rate through 2034. This trend illustrates the increasing demand for energy-efficient solutions that help industries not only meet productivity goals but also adhere to more stringent environmental standards. As companies continue to embrace automation technologies, the adoption of AC servo drives is likely to play a crucial role in driving both efficiency and sustainability in operations.

Integration with Smart Technologies: The Future of AC Servo Drives in IoT

The integration of AC servo drives with smart technologies represents a transformative shift in modern automation systems, particularly within the realm of the Internet of Things (IoT). As industries continue to embrace digital connectivity, AC servo drives highlight their versatility by enabling and enhanced control capabilities. This evolution not only enhances operational efficiency but also allows for predictive maintenance, significantly reducing downtime.

In this interconnected landscape, AC servo drives can be seamlessly integrated with IoT platforms, allowing for advanced monitoring and analytics. By harnessing data from these drives, manufacturers can fine-tune their processes and respond proactively to system demands. Additionally, the ability to remotely adjust parameters and configurations opens new avenues for flexibility and scalability in production lines, catering to rapidly changing market needs. This synergy between AC servo drives and smart technologies illuminates a promising future for automated systems, paving the way for smarter, more responsive manufacturing environments.

Scalability and Flexibility: Meeting Diverse Automation Needs with AC Servo Drives

AC servo drives are pivotal in modern automation systems, allowing for a high degree of scalability and flexibility that meets the diverse needs of various industries. According to the Integrated Servo Motor Market analysis, the demand for AC servo drives is projected to grow significantly, with the market driven by increasing automation in sectors such as automotive, electronics, and packaging. With the ability to easily adapt to different applications and production scales, AC servo technology offers manufacturers the agility required to respond to market changes and customize their processes.

Furthermore, the implementation of adaptive, real-time control through AC servo drives is critical for operations with complex requirements, such as those faced by manufacturers like Rutland Plastics. The ability to manage high mix production while maintaining precise temperature control enhances efficiency and productivity. Reports suggest that industries adopting these advanced drives can expect to see reductions in downtime and increases in overall output, further solidifying AC servo drives as a fundamental component in the pursuit of optimized automation solutions. As production demands evolve, the versatility of AC servo drives will continue to play a key role in shaping the future of industrial automation.

Understanding the Benefits of AC Servo Drives in Modern Automation Systems

| Dimension | Description | Benefit |

|---|---|---|

| Scalability | Ability to easily expand and adapt systems as needed. | Allows for future growth and requirement changes without major overhauls. |

| Flexibility | Capability to manage various applications and tasks. | Enables organizations to adjust quickly to market or production changes. |

| Performance | High precision and speed in motion control. | Enhances product quality and operational efficiency. |

| Energy Efficiency | Optimized power consumption during operation. | Reduces operational costs and environmental impact. |

| Integration | Compatibility with various control systems and equipment. | Facilitates seamless deployment across manufacturing setups. |

Reliability and Performance Metrics: Industry Standards for AC Servo Drive Efficiency

AC servo drives have become a crucial component in modern automation systems, aligning with industry standards that emphasize reliability and performance metrics. These drives are engineered to deliver optimal efficiency, which is essential for various applications, from manufacturing processes to robotics. By adhering to rigorous industry standards, AC servo drives ensure consistent operation and enhanced durability, contributing to reduced downtime and maintenance costs.

The increasing adoption of AC synchronous reluctance motors further highlights the shift towards advanced automation technologies. These motors, coupled with high-performance AC servo drives, offer benefits such as improved energy efficiency and precision control. Metrics such as torque output and response times are essential for assessing their effectiveness in different operational settings, particularly in the automotive sector where demand for high efficiency and reliability is paramount. As industries evolve, the integration of AC servo drives is expected to play a pivotal role in meeting the challenges of modern automation.

AC Servo Drive Efficiency Metrics

This chart illustrates the distribution of AC Servo Drives based on their efficiency metrics. The majority of the drives operate at a high efficiency level of 90% or more, which contributes to enhanced performance and reliability in automation systems.

Related Posts

-

Understanding the Advantages of AC Servo Drives in Modern Automation Solutions

-

Unlocking Efficiency: How Industrial Servo Motors Transform Automation in Manufacturing

-

Top Strategies for Maximizing Performance with Best AC Servo Drives

-

Explore the Technical Specifications of the Best Servo Drives and How to Choose the Right One for Your Needs

-

7 Essential Tips for Maximizing Performance with AC Servo Motors

-

Understanding the Fundamentals of AC Servo Technology: What You Need to Know