Why Choose Small Servo Motors for Your Next Project? Benefits and Applications Explained!

In today's rapidly evolving technological landscape, the choice of components for projects can significantly impact performance and efficiency. One component that has garnered attention for its versatility and precision is the small servo motor. Renowned industry expert Dr. Jane Smith, a leading figure in robotics engineering, emphasizes the importance of these motors by stating, "Small servo motors are essential in applications where space is limited, yet precision is paramount."

Small servo motors offer a range of benefits, including compact size, lightweight design, and exceptional control accuracy, making them ideal for various applications from robotics to automation. Their ability to provide precise positioning and smooth operation allows engineers and hobbyists alike to explore innovative designs without compromising performance. As we delve deeper into the advantages and applications of small servo motors, it becomes clear why they have become a staple in modern engineering projects.

Understanding the unique features and potential of small servo motors can empower designers to create more efficient and effective systems. Whether you are working on a delicate robotic mechanism or a complex automation project, the integration of small servo motors can elevate your work to new heights, paving the way for technological advancements and creative solutions.

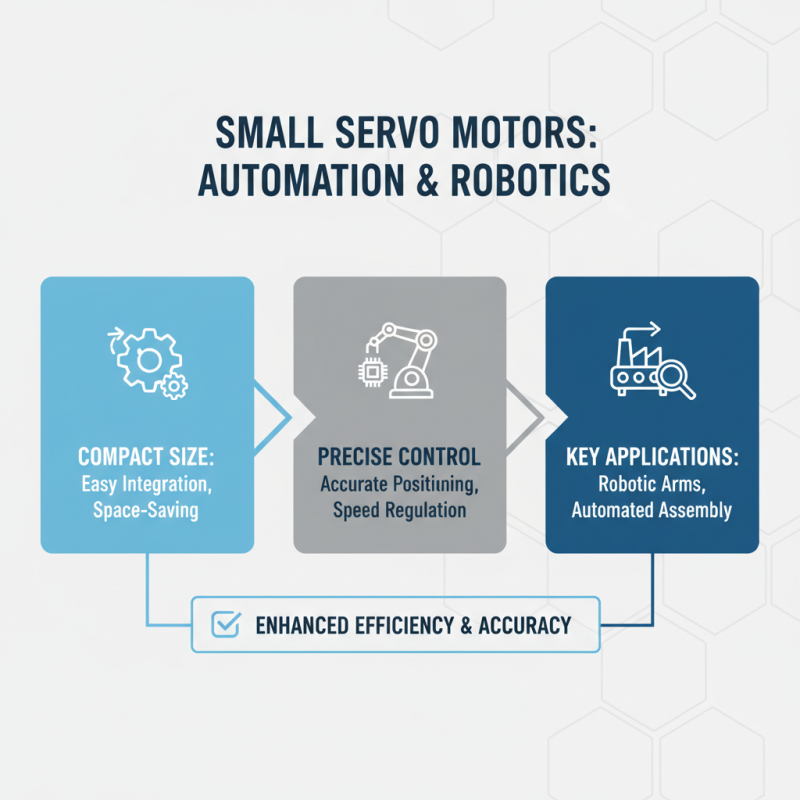

Benefits of Small Servo Motors in Automation and Robotics Applications

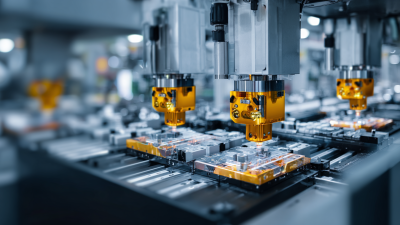

Small servo motors have become an essential component in the fields of automation and robotics due to their numerous benefits. First and foremost, their compact size allows them to be easily integrated into a variety of systems without adding significant bulk, making them ideal for applications where space is limited. Moreover, they offer precise control over motion, including accurate positioning and speed regulation, which is crucial for tasks requiring high levels of accuracy, such as robotic arms in manufacturing or automated assembly lines.

In addition to their size and precision, small servo motors are known for their reliability and efficiency. They can operate continuously under various load conditions, providing consistent performance over time. This reliability reduces downtime and maintenance costs, which is particularly valuable in large-scale automated systems. Their ability to respond quickly to control signals enhances the performance of robotics applications, allowing for smoother and faster operation, which is essential in environments that demand high productivity and quick turnaround times. Overall, the versatility and advantages of small servo motors make them a top choice for modern automation and robotics projects.

Key Features of Small Servo Motors: Precision, Speed, and Control

Small servo motors stand out in various applications due to their key features, including precision, speed, and control. Precision is perhaps the most significant advantage of small servo motors. These devices utilize closed-loop control systems that allow for real-time feedback, enabling them to achieve exact positioning and movement within tight tolerances. This level of accuracy is essential in applications such as robotics and CNC machines, where even minor deviations can lead to significant errors.

Speed is another critical attribute of small servo motors. They can accelerate and decelerate quickly, inherently making them suitable for dynamic environments where rapid response times are essential. This feature is particularly beneficial in automated systems and assembly lines, where tasks require quick adaptation to changing conditions or demands. The ability to adjust speed without compromising precision makes small servo motors an excellent choice for intricate tasks and high-performance applications.

Control capabilities further enhance the usability of small servo motors. With advanced control algorithms, these motors can execute complex movements and patterns, allowing users to program them for a variety of tasks. This flexibility opens the door to innovations in areas such as remote-controlled vehicles, hobbyist projects, and even medical devices, where both automated control and human interaction may be required. The combination of precision, speed, and control uniquely positions small servo motors as a versatile solution for many engineering challenges.

Why Choose Small Servo Motors for Your Next Project? Benefits and Applications Explained!

| Feature | Description | Application |

|---|---|---|

| Precision | Small servo motors offer high positional accuracy and repeatability, making them ideal for applications that require exact movements. | Robotics, CNC machines, and camera gimbals. |

| Speed | These motors can achieve rapid movement and quick response times, enhancing overall system performance. | Automated production lines, drone flight controls, and robotic arms. |

| Control | Small servo motors provide smooth and precise control over their movements, allowing for complex tasks to be performed with ease. | Remote-controlled vehicles, animatronics, and simulation applications. |

| Compact Size | Their small form factor allows for integration into tight spaces where larger motors would be impractical. | Wearable technology, compact robots, and small automation systems. |

| Power Efficiency | Small servo motors are designed to consume less power, helping to reduce operational costs and battery consumption. | Battery-powered devices, portable robots, and energy-efficient systems. |

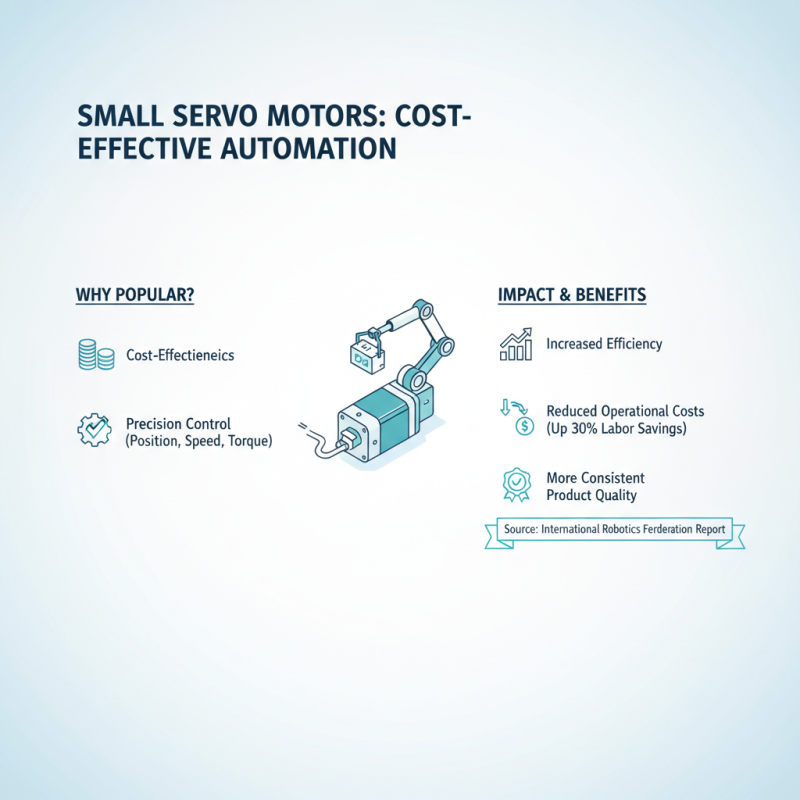

Cost-Effectiveness of Small Servo Motors in Various Industries

Small servo motors have gained popularity across various industries due to their cost-effectiveness and versatility. According to a recent report from the International Robotics Federation, the implementation of small servo motors in automation and robotics has increased efficiency while considerably reducing operational costs. In manufacturing sectors, companies have reported saving up to 30% on labor costs and achieving more consistent product quality by integrating these motors into their assembly lines. The ability to precisely control position, speed, and torque makes small servo motors invaluable in applications where accuracy is crucial.

Moreover, industries such as automotive and aerospace benefit significantly from the use of small servo motors, particularly in applications involving robotics and CNC machining. A study by the Global Servo Motors Market Analysis suggests that the demand for small servo motors is expected to grow by 8% annually through 2026, driven by their lower energy consumption compared to larger motors. This has prompted companies to transition to more efficient systems, further aligning with sustainability goals. By choosing small servo motors, industries not only enhance their operational efficiency but also contribute to reducing overall energy expenditures.

Industry Trends: Small Servo Motors in Consumer Electronics and IoT

The rise of small servo motors in consumer electronics and IoT applications highlights a significant trend in the industry towards miniaturization and enhanced efficiency. These compact devices are increasingly being integrated into everyday electronics, from smart home appliances to wearable technology. Their ability to deliver precise control and high torque in a small form factor makes them ideal for applications that require agility and responsiveness. For instance, in robotics, small servo motors can facilitate nuanced movements, enabling devices to perform intricate tasks that were previously difficult to achieve with larger motors.

Moreover, the proliferation of IoT devices has created a burgeoning demand for small servo motors that can seamlessly interact within smart ecosystems. As consumer expectations evolve, the need for more advanced functionalities in gadgets increases. Small servo motors are at the forefront of this evolution, providing the ability to control various features, such as camera gimbals, automated blinds, and even robotic vacuum cleaners. Their compact design and energy efficiency not only save space but also reduce energy consumption, aligning with the increasing emphasis on sustainability in electronic design. As technology continues to advance, the role of small servo motors will only grow, driving innovation in the consumer electronics and IoT sectors.

Comparative Analysis: Small Servo Motors vs. Traditional Actuators

When considering actuator options for various engineering projects, small servo motors distinguish themselves from traditional actuators through several key advantages. According to a report by the International Federation of Robotics, servo motors offer a greater efficiency in energy consumption, often outperforming traditional linear actuators by up to 50%. This efficiency not only reduces operational costs but also prolongs the lifespan of the components, ultimately leading to a more sustainable solution for manufacturers who require precision and reliability in automated processes.

Furthermore, small servo motors excel in responsiveness and positioning accuracy. With typical resolutions of up to 12 bits, they provide a level of control that traditional actuators struggle to match. A study published by the Association for Advancing Automation indicated that manufacturers utilizing servo technology report a decrease in cycle times by approximately 30%, allowing for faster production rates in competitive industries. The compact size of these motors also enables design versatility, making them ideal for applications in robotics, medical devices, and consumer electronics, where space constraints are often a significant consideration.

In applications requiring intricate movements or rapid adjustments, small servo motors can outperform traditional actuators not only in performance but also in adaptability to varying load demands. As industries continue to prioritize efficiency and compactness, the shift towards incorporating small servo motors is likely to gain traction, providing tangible benefits across numerous sectors.

Comparison of Small Servo Motors and Traditional Actuators

Related Posts

-

Advanced Solutions for Enhancing Efficiency with Hollow Shaft Servo Motors

-

2025 Guide: How to Choose the Best Small Servo Motor for Your Robotics Project

-

Overcoming Common Challenges with Servo Motors: A Deep Dive into Performance and Reliability Issues

-

Electric Servo Motor Showdown: Which Type Reigns Supreme in Performance and Efficiency?

-

7 Essential Tips for Choosing the Best High Torque Servo Based on Performance Data

-

Unlocking Efficiency: How Industrial Servo Motors Transform Automation in Manufacturing