Understanding the Advantages of Integrated Servo Motors in Modern Automation

In the rapidly evolving landscape of modern automation, the role of integrated servo motors has become increasingly prominent. According to a report by Research and Markets, the global servo motor market is projected to reach $9.2 billion by 2026, growing at a CAGR of 6.5% from 2021. This growth is fueled by the rising demand for precision and efficiency in manufacturing processes, where integrated servo motors provide unparalleled performance due to their compact design and built-in control capabilities. These motors not only reduce the complexity of assembly but also enhance responsiveness and energy efficiency, making them a preferred choice for industries seeking to streamline operations.

As we delve deeper into the myriad advantages of integrated servo motors, it becomes clear that their integration is not just a technological trend, but a crucial step towards achieving smarter and more efficient automation solutions.

Advantages of Integrated Servo Motors in Industrial Robotics Applications

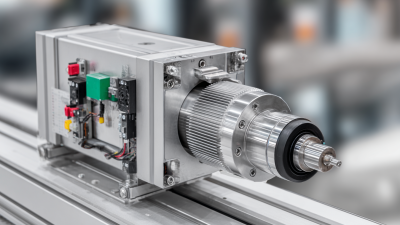

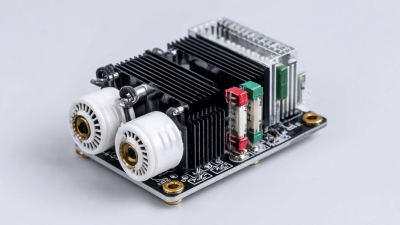

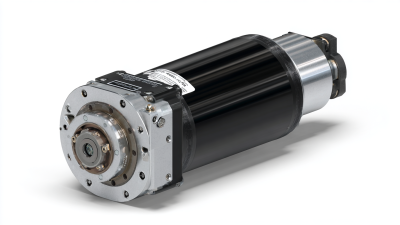

Integrated servo motors are revolutionizing the field of industrial robotics by combining precision control with compact design. One of the most significant advantages they offer is reduced footprint; by integrating the motor and drive technology into a single unit, they not only save valuable space but also simplify the machine design. This compactness enables robots to work in tighter spaces, enhancing flexibility in production environments.

Moreover, integrated servo motors provide superior performance through seamless communication between the components. This synergy allows for faster response times and improved accuracy in movements, vital for tasks requiring high precision, such as assembly and material handling. Additionally, the reduction in wiring and external components enhances reliability and decreases the likelihood of failure. This efficiency translates into lower maintenance costs and increased uptime, allowing manufacturers to maximize productivity in their operations.

Enhanced Precision and Speed with Integrated Servo Motors

The advancement of integrated servo motors is revolutionizing modern automation by delivering unparalleled precision and speed. According to a recent report by MarketsandMarkets, the global servo motor market is expected to grow from $7.6 billion in 2020 to $12.2 billion by 2025, driven primarily by the increasing need for high-performance and efficient automation systems. Integrated servo motors combine the motor and drive into a single unit, significantly reducing size and simplifying installation, which results in increased productivity and lower operational costs.

Enhanced precision is a critical advantage of integrated servo motors. They offer superior feedback control, enabling tight positioning for applications that require accurate repeatability. This precision becomes particularly essential in sectors such as robotics and manufacturing, where even minor deviations can lead to substantial errors. In fact, a study by the International Federation of Robotics highlighted that automation in manufacturing can improve productivity by up to 30%, underscoring the importance of advanced technology in streamlining processes.

**Tips for Implementing Integrated Servo Motors:**

1. Assess Your Application Requirements: Determine the necessary torque, speed, and precision needed for your specific automation tasks.

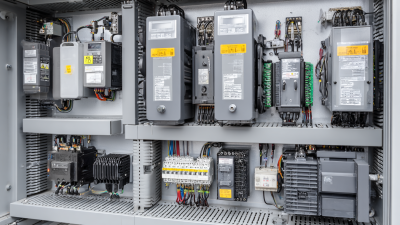

2. Choose the Right Controller: Ensure compatibility with your integrated servo motors to maximize performance and efficiency during operation.

3. Consider Energy Efficiency: Look for servo motors that offer regenerative braking capabilities to reduce energy consumption and cut operational costs.

Cost-Effectiveness of Integrated Servo Motors in Manufacturing

The cost-effectiveness of integrated servo motors in modern manufacturing is transforming industrial automation. These motors combine precision control with a compact design, eliminating the need for separate components, which significantly reduces overhead costs. By integrating the motor and drive into a single unit, manufacturers can streamline assembly processes, minimize wiring, and reduce installation time, leading to a quicker return on investment.

Tips for Implementing Integrated Servo Motors: Consider starting with a pilot project to assess the efficiency gains before a full-scale implementation. Additionally, ensure proper training for your staff to maximize the technology's potential and reduce downtime.

Moreover, the growing demand for high-performance automation solutions emphasizes the need for cost-effective technologies. Integrated servo motors not only facilitate energy savings and enhanced productivity through advanced control features but also support sustainability initiatives by adhering to strict emissions policies put forth by regulatory bodies. This alignment with environmental goals makes these motors an attractive choice for forward-thinking manufacturers.

Tips for Sustainable Automation: Evaluate energy consumption and aim for motors that meet or exceed minimum efficiency standards. Regular maintenance and updates on software can also enhance performance and longevity, ensuring that your investment continues to yield significant savings over time.

Improving Energy Efficiency through Integrated Servo Motor Solutions

The shift toward energy efficiency in motor technologies is becoming increasingly critical in modern automation, particularly with the rise of integrated servo motor solutions. These advanced systems not only streamline performance but also contribute significantly to energy conservation. For instance, the global energy-efficient motor market, expected to reach a valuation of USD 48.52 billion by 2025, underscores the growing demand for more efficient technologies in various applications (source: Market Analysis Report).

Integrated servo motors exemplify this trend by offering higher precision and enhanced control, which lead to reduced energy consumption. Reports indicate that implementing these motors can result in energy savings of up to 80% in specific applications, reflecting their role in sustainable manufacturing practices, especially in the context of Industry 4.0. As businesses adopt these technologies, they not only optimize operational efficiency but also align with the global push towards energy reduction, taking significant steps towards a more sustainable future.

Energy Efficiency Comparison of Integrated Servo Motors

Real-World Applications: Integrated Servo Motors in Packaging and Assembly Lines

Integrated servo motors are transforming the landscape of modern automation, particularly within packaging and assembly lines. These advanced systems combine motor and controller into a single unit, streamlining installation and reducing the footprint of machinery. In high-speed packaging environments, integrated servo motors enable precise control and synchronization, which is crucial for maintaining throughput and minimizing downtime. They offer enhanced performance in tasks such as filling, capping, and labeling, where speed and accuracy are paramount.

The impact of integrated servo motors extends beyond mere efficiency; they also enhance adaptability in assembly lines. In industries ranging from electronics to food processing, integrated servo motors can be easily reconfigured for varying product sizes or types, facilitating quick changeovers. This flexibility allows manufacturers to respond rapidly to market demands without sacrificing productivity. Furthermore, their built-in feedback mechanisms provide real-time data, enabling predictive maintenance and reducing the likelihood of unexpected failures. By integrating these technologies, businesses not only optimize their operations but also position themselves for future growth in an increasingly competitive landscape.

Related Posts

-

Overcoming Common Challenges with Servo Motors: A Deep Dive into Performance and Reliability Issues

-

7 Reasons Why Your Factory Needs an AC Servo Motor Today

-

Future Innovations in Servo Motor Drivers Shaping Global Industry Trends in 2025

-

Future Trends in Technology 2025 How to Choose the Best Servo Amplifier for Your Applications

-

Top Strategies for Maximizing Performance with Best AC Servo Drives

-

Innovative Solutions for Achieving Maximum Efficiency with Best DC Servo Motors