Exploring 2025 Tech Trends: How to Choose the Best Frameless Motor for Your Business Needs

As we navigate the technological landscape of 2025, businesses are increasingly turning to innovative solutions to enhance their operations, with frameless motors emerging as a key player in this evolution. According to a recent report by MarketsandMarkets, the global servo motor market is expected to reach $9.07 billion by 2025, driven by a growing demand for automation and precision engineering across various industries. Frameless motors, characterized by their compact design and high performance, are particularly suitable for applications requiring high torque and low inertia. Consequently, understanding how to select the right frameless motor tailored to specific business needs can significantly impact efficiency and productivity. As industries strive for more streamlined processes and reduced operational costs, the ability to make informed decisions about motor technology has never been more critical.

Identifying Key Features of Frameless Motors for Business Applications

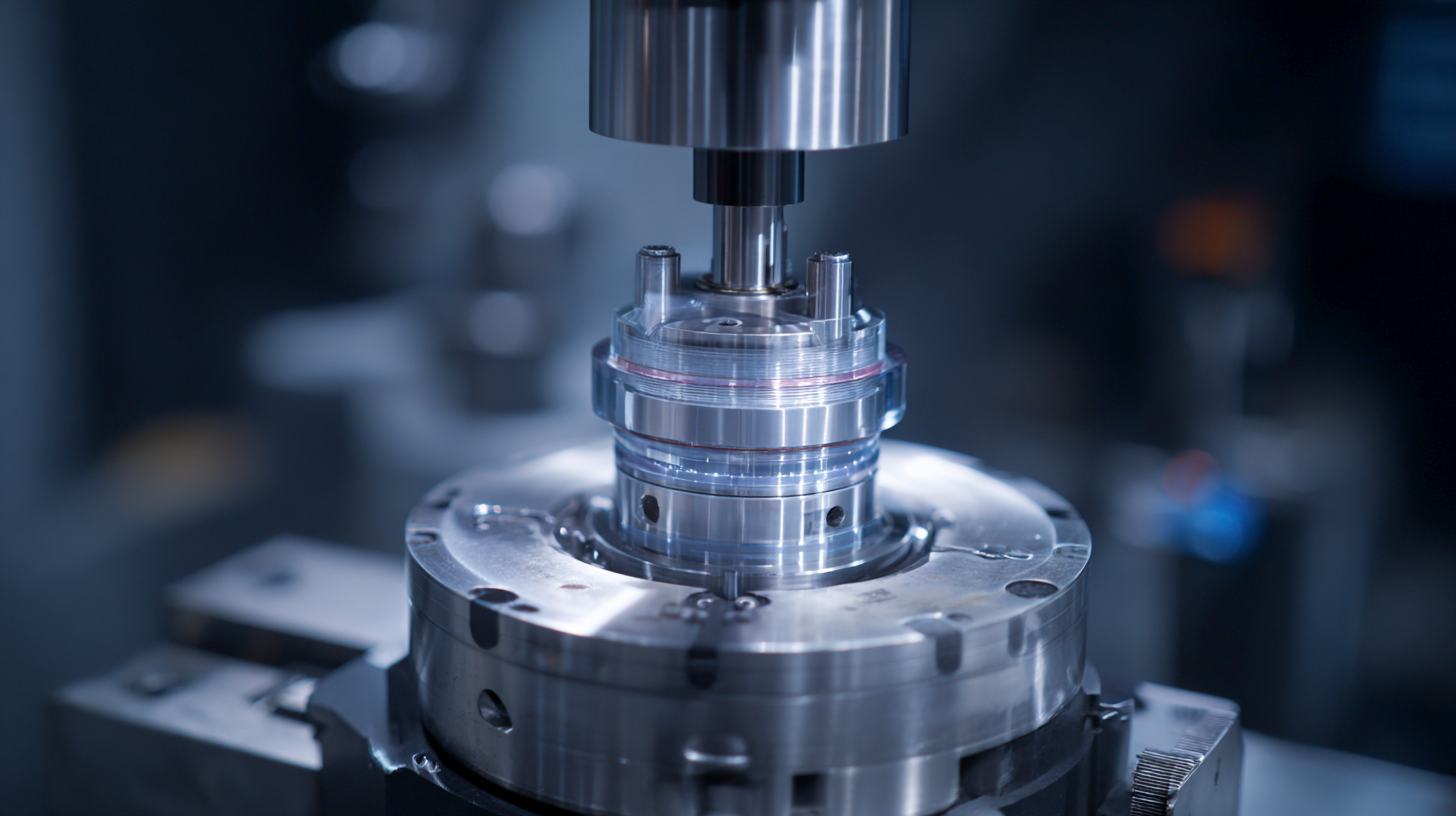

When it comes to selecting a frameless motor for your business applications, understanding the key features is essential for maximizing efficiency and performance. Frameless motors are known for their compact design, allowing for seamless integration into a variety of systems. They provide high precision and torque density, making them ideal for applications that require accuracy and reliability.

Tip: Consider the load requirements of your specific application. A motor with a higher torque rating may be necessary for heavy-duty tasks, whereas lighter applications might benefit from a more compact, energy-efficient model.

The choice of feedback systems is another critical factor. Motors equipped with encoders or other feedback mechanisms can offer enhanced control and positioning accuracy. This is crucial in environments where precision is paramount, allowing for real-time adjustments based on performance data.

Tip: Evaluate the compatibility of the feedback system with your existing technology infrastructure. An easily integrated feedback mechanism can save both time and resources during implementation.

Understanding the Different Types of Frameless Motors Available

Frameless motors are becoming increasingly popular in various industries due to their compact design and versatile applications. Understanding the different types of frameless motors available is crucial for businesses looking to integrate them into their operations. The two primary types are brushless DC (BLDC) motors and stepper motors.

BLDC motors are known for their high efficiency, low maintenance, and ability to operate at high speeds, making them ideal for applications such as robotics, conveyor systems, and precision machinery. Their controller systems allow for smooth and responsive performance, which is vital for dynamic environments.

Frameless motors are becoming increasingly popular in various industries due to their compact design and versatile applications. Understanding the different types of frameless motors available is crucial for businesses looking to integrate them into their operations. The two primary types are brushless DC (BLDC) motors and stepper motors.

BLDC motors are known for their high efficiency, low maintenance, and ability to operate at high speeds, making them ideal for applications such as robotics, conveyor systems, and precision machinery. Their controller systems allow for smooth and responsive performance, which is vital for dynamic environments.

On the other hand, stepper motors excel when precise positioning and control are required. They operate in discrete steps, making them suitable for applications that demand exact movements, like 3D printers and CNC machines. Additionally, stepper motors are often more straightforward to control than BLDC motors, making them a preferred choice for less complex systems.

When choosing the right frameless motor for your business needs, it’s essential to consider these variants' unique strengths and how they align with your operational requirements, ultimately ensuring you select the best fit for your technological landscape.

Evaluating Supplier Reputation and Reliability for Quality Assurance

When selecting a frameless motor for business applications, evaluating supplier reputation and reliability is essential for ensuring quality assurance. According to a report by Allied Market Research, the global market for frameless motors is expected to reach $1.9 billion by 2025, highlighting the increasing reliance on these advanced technologies across various sectors. As the competition grows, it becomes imperative not only to choose the right product but also to choose a trustable supplier who demonstrates proven reliability and support.

One practical approach is to examine supplier credentials and customer reviews to assess their track record. A study from the Institute of Electrical and Electronics Engineers (IEEE) indicates that 72% of companies prioritize supplier reliability when considering a new component for system integration. Engaging with industry peers and leveraging platforms like LinkedIn for insights on suppliers can also provide valuable feedback regarding their reputation. By thoroughly vetting these factors, businesses can mitigate risks and ensure their investment contributes to operational efficiency and productivity in the long run.

Assessing Cost vs. Performance: Finding the Right Balance

In the rapidly evolving technology landscape of 2025, businesses are faced with the critical task of balancing cost and performance when selecting a frameless motor. According to a recent report by Grand View Research, the global electric motor market is expected to reach $162 billion by 2025, driven by demands for high efficiency and advanced features. This statistic underscores the significance of choosing the right motor to ensure both operational excellence and financial viability.

When evaluating frameless motors, companies should consider not only the initial investment but also the long-term operational costs and performance benefits. For instance, a study by MarketsandMarkets indicates that the rise in automation and smart manufacturing is pushing the demand for high-performance motors, which can enhance productivity by up to 30%. Thus, investing in a higher-performing motor could yield significant returns through increased efficiency and reduced downtime. Striking the right balance between cost and performance will ultimately influence a business's scalability and competitive edge in the market.

Performance vs. Cost Analysis of Frameless Motors for 2025

Navigating the Supply Chain: Tips for Engaging with Manufacturers

When navigating the complex landscape of supply chains, engaging effectively with manufacturers is crucial for businesses looking to implement the best frameless motors. As industries increasingly lean towards automation and advanced technologies like AI-driven solutions in drones and robotics, understanding the intricacies of these supply chains will help companies make informed decisions. For instance, the recent advancements in automated mapping have prompted considerable workforce reductions in companies that are not adapting quickly enough, underscoring the need for businesses to stay competitive in choosing reliable manufacturing partners.

Building robust relationships with manufacturers begins with clear communication about your specific needs and expectations. Proactively sharing insights on potential challenges can help in mutual strategizing, leading to enhanced collaboration. Additionally, considering the globalization of the supply chain, tapping into emerging markets like autonomous navigation systems can present unique opportunities.

With the logistics robot market projected to grow significantly, businesses must keep an eye on innovative supply chain strategies to ensure they are sourcing the best technologies available for their operational demands.